|

Charlotte Stonestreet

Managing Editor |

| Home> | AUTOMATION | >Vision Systems | >Demystifying machine vision |

Demystifying machine vision

16 April 2019

At the 2019 UKIVA Show in Milton Keynes this June, SICK will show how machine vision is being demystified for a growing number of adopters, backed by greater accessibility to ‘all-in-one’ intelligent vision sensors powered by ready-made software applications.

Recently appointed as vice-chairman of UKIVA, SICK’s Neil Sandhu will deliver two presentations to delegates that put the case for removing the complexity that can surround implementing a vision solution, empowering users to set up vision systems, including more difficult 3D applications, with ease.

“Machine vision has been a headache too far for many engineers looking to improve their production or materials handling processes with better standards of inspection. Programming a reliable system to process the data from a vision camera has been feared in the past as something of a black art,” says Sandhu who is SICK’s UK Product Manager for Imaging, Measurement & Ranging.

“But now rapid advancements in camera technology combined with intelligent on-board processing capability have brought high-performance applications within the reach of many production teams who would previously have felt excluded from them. So, the time has come to present a more accessible and democratised outlook for vision in future and to encourage more users to enjoy the benefits.”

Technology demonstrations

SICK’s technology demonstrations at the Show will underline the company’s ambition for intelligent devices like the Inspector P 2D and the Trispector 1000 3D smart vision sensors to work in a similar way to smart phones powering ready-made applications that are easy to set up and use, selected via a central cloud-based repository of industry solutions.

Central to this vision is SICK’s AppSpace platform for development and pooling of software applications, for which a growing number of solutions are now being realised both by SICK and by its automation partners.

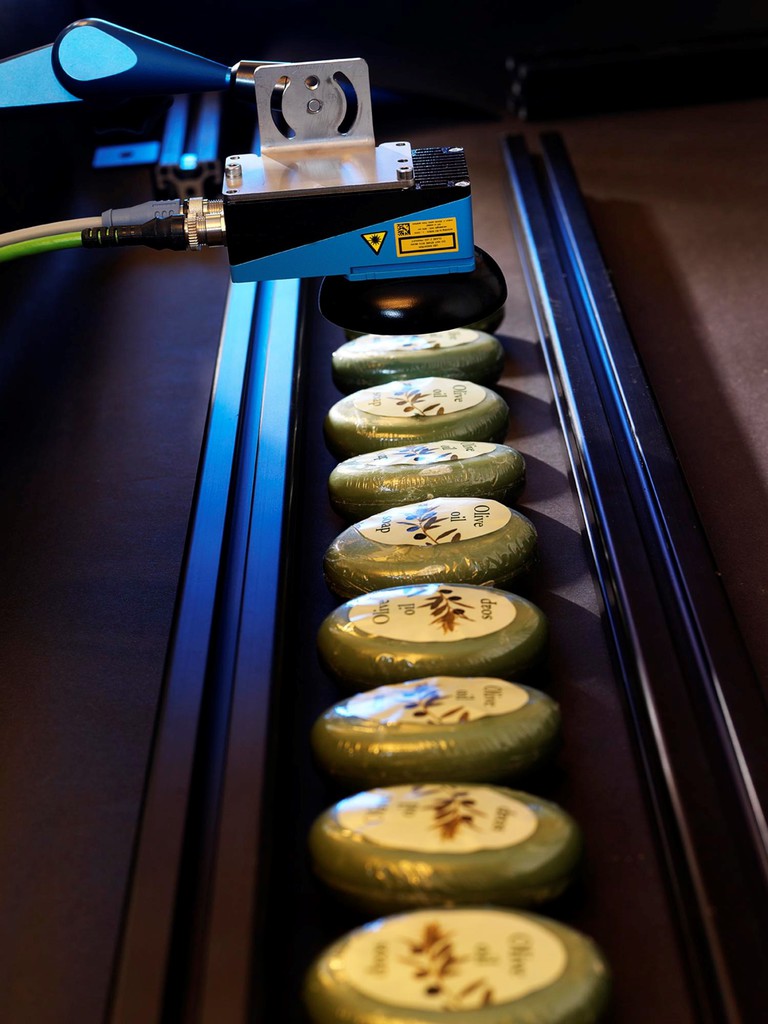

On show at UKIVA will be the new 4Sight Automated Print Inspection System developed in SICK AppSpace with packaging automation specialists Autocoding Systems. The breakthrough of 4Sight is that it communicates directly with common printer types, such as inject and laser thermal transfer. It can therefore automatically recognise and inspect the alphanumeric code applied by the printer and seamlessly continue the inspection whenever a code is updated, for example with a new date or batch number. There is no requirement to “teach” the camera what to look for, or for fixturing using an edges or logos. High-resolution, high-reliability and high-speed image processing are assured by hosting the solution on the SICK Inspector P vision sensor.

SICK will also demonstrate its entry-level robot guidance solutions using smart 2D and 3D vision sensors. The Inspector PIM60 URCap integrates SICK’s Inspector PIM60 2D vision sensors with Universal Robots. Simple to set up and use, the combination delivers a powerful toolkit for creating a vision-guided robot task with minimum time and effort. Configuration is achieved in minutes through the UR controller or the SICK Inspector PIM60 without need for an additional PC.

SICK’s Trispector P Beltpick is a 3D vision guidance solution for robot picking with improved z-axis control, enabling gentle handling of complex shapes and profiles, or picking products with variable heights from a conveyor, for example. The system adapts the robot’s picking action to the height of each individual product, reducing the risk of damage. With ‘plug-and-play’ support for ABB, Staubli and Universal Robots, users have access to a range of SICK AppSpace apps for belt picking applications. Other robot manufacturers can also be integrated with the new system.

The UKIVA Machine Vision Conference will take place at the Marshall Arena, Milton Keynes on 6 June 2019.

- Motion Control

- IO-Link added to identification devices

- Next generation sensor

- Easy set-up contour-based navigation on any mobile platform

- Next-generation 2D vision camera with integrated AI functionality

- All-in-one muting sets

- Easy, standalone RFID

- Light curtain alternative

- SICK shrinks UHF RFID read/writing

- On-premise data intelligence platform

- Turnkey hovercraft drivetrain guarding

- More Ways of Identifying Objects

- HD Machine Vision

- Bespoke Vision Sensor Packages

- B&R NEW WEBSITE

- View Images & Overlay Graphics

- Get A Lock On 3D Measurement

- Entry-level vision system

- Multipix will launch the NEW Datalogic MATRIX 450

- Process, print and packaging inspection systems on show