|

Charlotte Stonestreet

Managing Editor |

| Home> | AUTOMATION | >Robots | >Boosting productivity never looked so easy |

Boosting productivity never looked so easy

17 October 2025

Compact, lightweight and straightforward to program, cobots are easy to deploy and adapt as requirements change. Julian Ware explains how they can deliver higher productivity for companies of every size

With people and robots working side-by-side, users can benefit from a combination of the problem-solving capabilities, insights and adaptability-to-change of human operators, together with the tireless precision and tolerance of repetitive tasks provided by robots. In fact, cobots can add value at almost every stage of production, thanks to their combination of relative simplicity and a compact footprint.

The ability of collborative robots, or cobots, to work safely alongside humans without the need for physical guards reduces the overall footprint of robotic work cells, making cobots ideal for applications where users want to maximise productivity without compromising on safety. Applications can include both continuous and intermittent collaboration, such as final trim and assembly in automotive manufacturing where some human interaction is needed.

Opening up for SMEs

The global market for cobots is expected to grow from US$1.42 billion in 2025 to reach US$3.38 billion by 2030, according to a recent report from Markets and Markets. That’s a CAGR of 18.9%.

Much of this surge in popularity comes from the unprecedented ability of cobots to appeal to SMEs, thanks to their accessibility in terms of price and ease of use. While other robotic automation systems continue to evolve to meet the demands of high-volume industrial production, the arrival of smaller systems such as ABB’s YuMi and GoFa cobots is game-changing for SMEs and other low-volume/high-mix production situations.

Cobots are designed to fit easily into existing production lines, thanks to their flexible mounting options. They are smaller and generally rely less on peripheral equipment, reducing the upfront investment needed for a work cell in many applications.

Smarter, more straightforward control and programming is another key driver, enabling cobots to tackle a wider range of varied applications than previously. It also means that cobots can swap between products and be trained to work with new products quickly and easily.

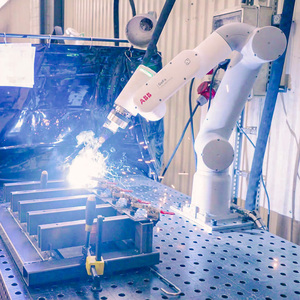

ABB’s cobot welding package is a good example. It uses a GoFa cobot equipped with a simplified auto-generated program selector tool that enables users to create welding sequences in less than 30 seconds. By eliminating the need for a ‘teach’ pendant, the package cuts programming time by 70 percent and removes the need for operators to have prior experience with robots.

Plug the talent gap

The labour squeeze is yet another factor driving uptake. While manufacturers of all sizes face recruitment headaches, SMEs operating in high-labour-cost countries often find it more difficult to readily outsource to low-cost countries in the same way as their larger rivals. Cobots not only reduce the need for manual labour, but can work tirelessly to deliver higher quality, enabling businesses to redeploy their scarce human workers to carry out tasks that add more value and make better use of their abilities.

Features such as lead-through programming and user-friendly touch screen interfaces allow operators with no previous experience to quickly program the robot. Offline simulation tools such as ABB’s RobotStudio also allow operators to simulate an application and refine a robotic installation in a virtual environment, without impacting on their real-world production processes. This helps reduce the time taken to get the robot up and running, which is ideal for organisations that have short product cycles.

The plug-and-play qualities of modern cobots mean they can be installed quickly and easily, minimising interference with production processes. Their small footprint and portability make cobots suitable not only for automating the kind of production lines where robots might already be a familiar sight, but also for more diverse applications in other industries such as food and pharma.

More companies are considering the possibilities offered by robotic automation in general, and cobots in particular, as a way of shoring up their workforce. These possibilities will grow as robotic technology becomes even safer, more adaptable and easier to use. Suppliers and their partners are working constantly to develop enhanced software features such as artificial intelligence (AI) and machine vision to increase the capabilities of robotic systems, even as they become easier to use.

Julian Ware is UK and Ireland sales manager at ABB Robotics

For more information, visit

- Vision-powered autonomy

- How cobots can encourage automation uptake

- RobotStudio gets generative AI assistant

- Condition-based maintenance for robots

- Automotive manufacturers rethinking JiT

- ABB unveils its smallest industrial robot

- YuMi waves the checkered flags at unveiling of Formula E Gen2 car

- Robotics role at point of consumption

- Seminar shows how to get ahead through a switch to robots

- Flexible robotic handling solutions

- Balls to Gravity

- ROBOTS GIVE FASTER CELL TOOL CHANGE TIMES

- ROBOT FOR DELICATE ASSEMBLY

- NUMBER OF ROBOTS IN UK ON THE RISE

- The future is bright - The future is automation!

- High Demand For Grant

- More Capacity, Less Space

- FREEBIRD - THE THIRD DIMENSION

- PRECISION ROBOT CELL FOR THE PHARMACEUTICAL INDUSTRY

- ROBOT SALES REACH ALL TIME HIGH