|

Charlotte Stonestreet

Managing Editor |

| Home> | MACHINE BUILDING & ENGINEERING | >Materials & Components | >Spring machined from solid replaces wire wound spring |

Spring machined from solid replaces wire wound spring

20 August 2013

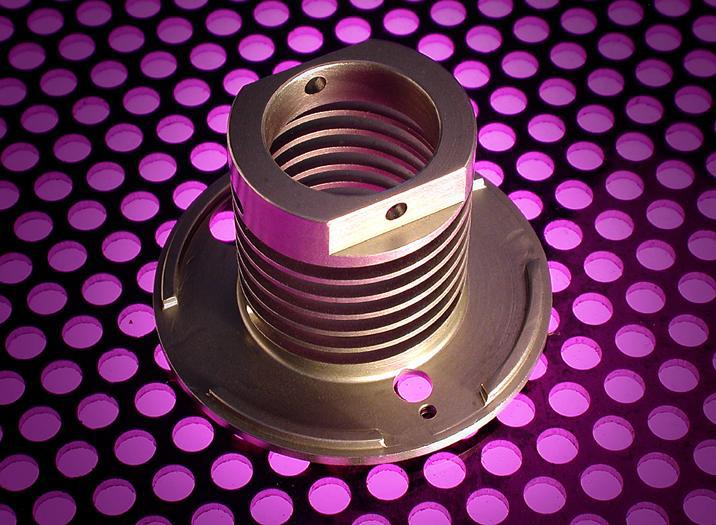

Demonstrating the capabilities of the machined spring product, Abssac recently addressed the question: Would Abssac be able to retro-fit a spring now being used as a buffer spring in a fuel control system?

The spring unit should compress and extend 2mm but deliver an accurate spring rate over a set life time. The current wire wound spring was not providing an accurate spring rate over time and each spring had to be rate tested and certified before fitting. Normal rate accuracies were ranging from +/-15% and were not linear in rate.

As the name suggests, the machined spring is machined from a single piece of material. This not only allows one, two, three or more spring elements to be machined into the single part but due to the geometry of the coil, the spring rate is totally linear. In fact spring rate tolerance can be as good as +/- 1% if required with the machined spring.

The machined spring supplied improved efficiency of the application, reduced parts inventory and each spring supplied was certified on rate so could be fitted straight into the application.

Stand E35