|

Charlotte Stonestreet

Managing Editor |

ARTICLE

Maximum process speed & precision

02 June 2014

When it comes to implementing packaging solutions that fill the correct amount while reducing the amount of packaging materials, or, indeed, reducing the energy consumption of the entire process chain, implementing PC Control ensures that the consumption of resources is reduced to the minimum.

Beckhoff Automation's XFC ("eXtreme Fast Control”) technology has I/O response times of <100μs so the process can be controlled with exceptional precision and repeat accuracy. With no need for special hardware, XFC implements extremely fast and accurate control solutions for packaging machines.

PC- and EtherCAT-based control ensures perfectly synchronised processes and motion control sequences with shorter cycle times for more throughput. The technology’s quick and precise response to printing marks makes it possible to save on packaging material, for example by placing products more closely together in blister packs, which reduces the amount of sealing foil needed as well as any waste.

MORE FROM THIS COMPANY

- New multi-axis robot system

- Many-core machine control

- Beckhoff expands UK training capacity

- ‘Plug & Work’ bus terminals

- Flexible control for food manufacturing

- Expanded Toolset

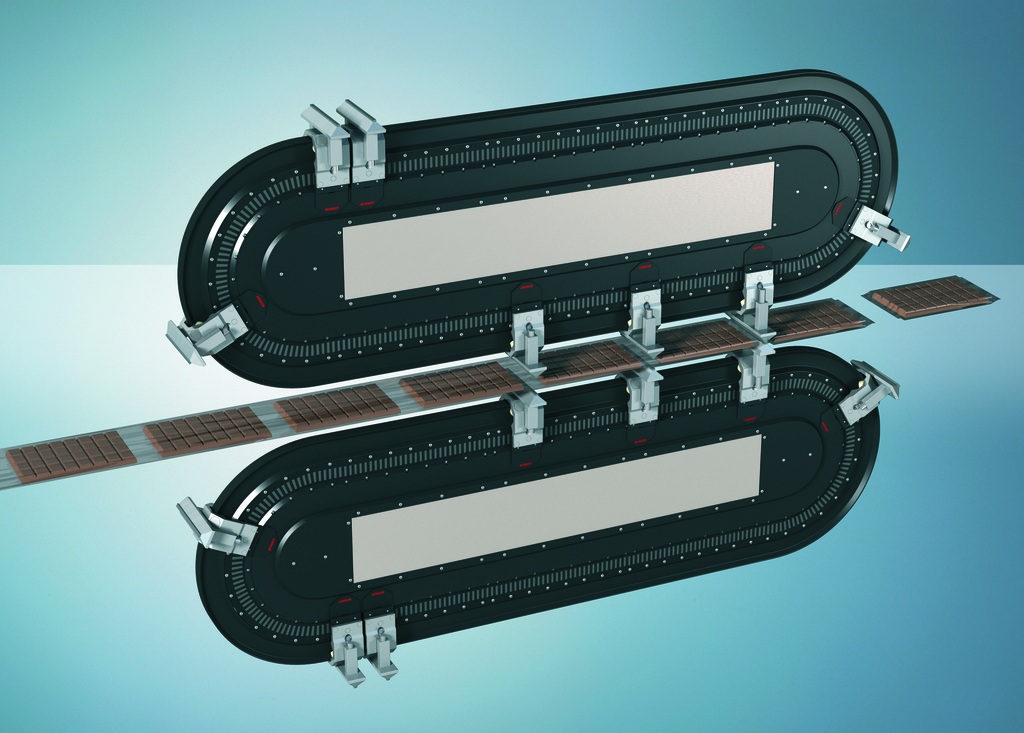

- No cable technology linear transport system

- 10 reasons to choose PC-based control

- Levelling the digital playing field

- Revolutionary linear transport system

RELATED ARTICLES

- Reduce Fault Times

- Vision Control Makes The Cut

- MULTIPLE PROTOCOL CONVERSION

- MAKE SURE YOU CATCH THE RIGHT BUS

- Smarter, Faster & More Compact Robot Controller

- What Does Windows 8 Mean For Test & Measurement?

- Thyristor Stack Controllers

- Easy To Automate

- Understanding Thyristor Control

- Introduction to embedded control and monitoring webcast

OTHER ARTICLES IN THIS SECTION