|

Charlotte Stonestreet

Managing Editor |

| Home> | POWER TRANSMISSION | >Bearings | >Bearings improve energy efficiency |

Editor's Pick

Bearings improve energy efficiency

25 February 2015

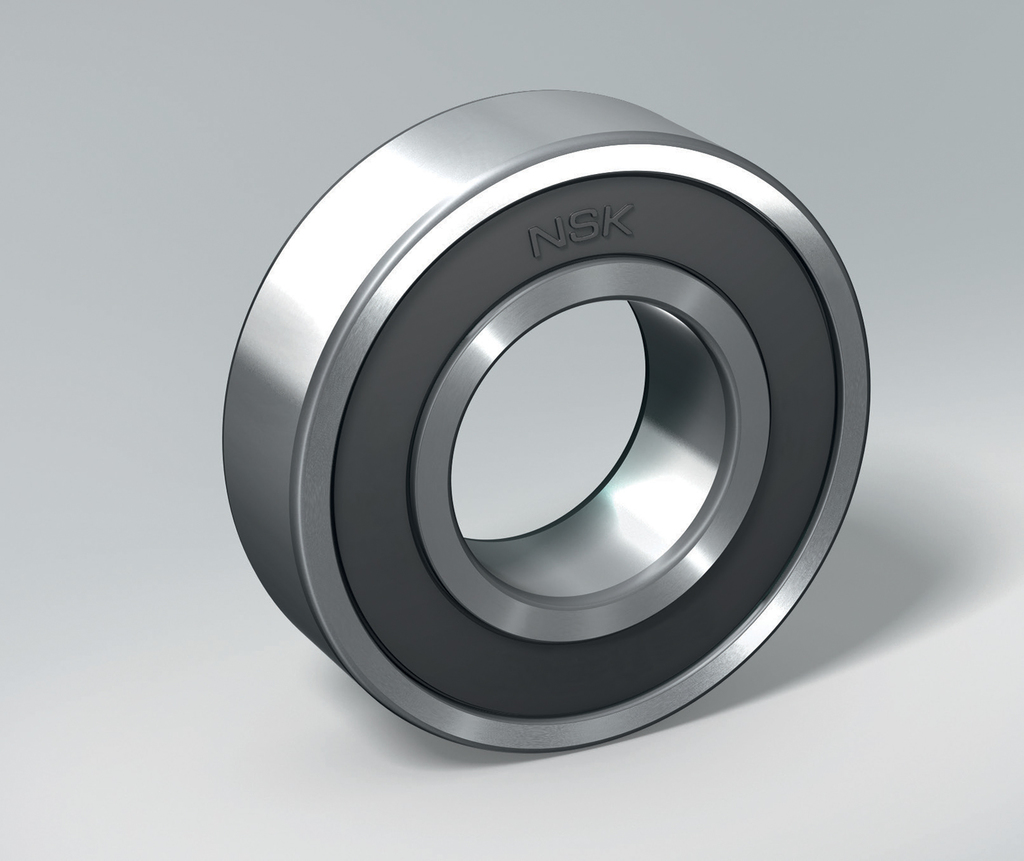

Within the global automotive sector, NSK has worked to produce low torque bearings which help to reduce power consumption and emissions. Now these advances in engineering design are being applied to general purpose, deep groove ball bearings, which are used in a wide range of industrial applications.

To help designers and customers alike, NSK has developed a series of improvements for bearing design and manufacture. These have resulted in standard deep groove ball bearings demonstrating up to a 47% torque saving for high speed domestic appliances compared to conventional bearings of the same size. This helps to improve efficiency and therefore reduce energy consumption; two features which will appeal to every industrial sector.

NSK has also made several developments in tribology and material technology as well as advancements in steel cleanliness to produce a significantly improved steel fatigue life.

- More counterfeit NSK merchandise uncovered

- Optimise bearings to avoid downtime

- Higher dynamics for pick-and-place machines

- NSK’s fight against counterfeiting continues

- NSK completes acquisition of Brüel & Kjær Vibro

- Bearing failures overcome

- Recycling plant saves over €50,000 per year

- Online jaw crusher bearing training

- Bearings cater for speed or load

- First NSK Certified AIP Partners named