|

Charlotte Stonestreet

Managing Editor |

| Home> | AUTOMATION | >Cutting | >Modular transport system |

| Home> | AUTOMATION | >Handling & Logistics | >Modular transport system |

| Home> | CONTROLS | >Motion Controls | >Modular transport system |

Modular transport system

18 June 2015

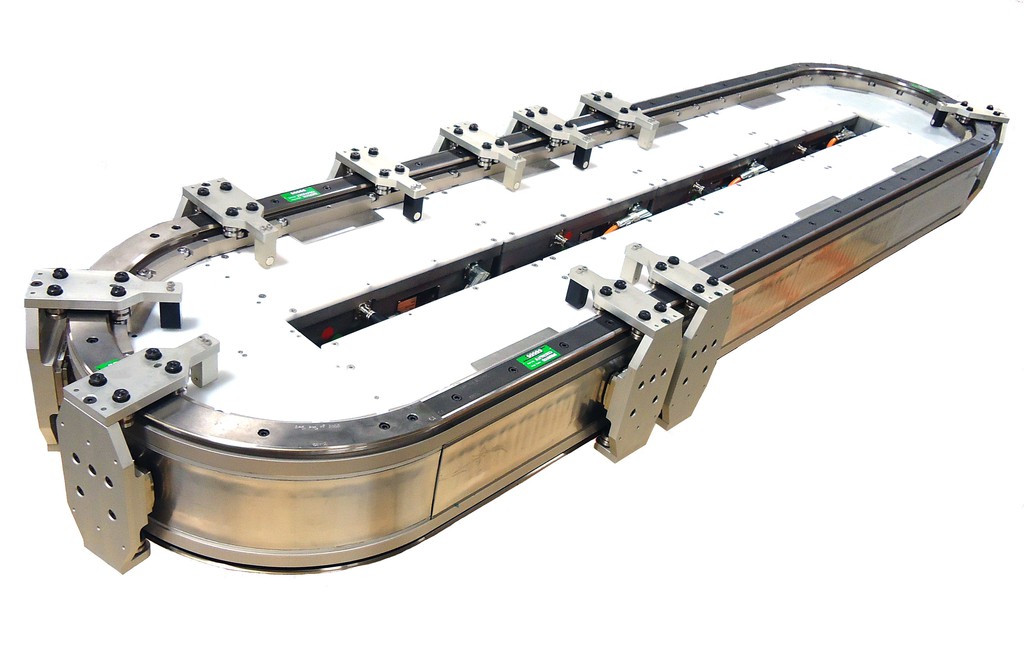

Rockwell Automation’s iTRAK is a modular, scalable motion control system that provides independent control of multiple magnetically propelled movers on a track.

The simple configuration and patented pitch-less technology solves different motion and speed needs. It enables production/handling systems and assembly lines to be readily designed with the aid of a number of accurately positioned carriages.

Several carriages, consisting of a frame and a linear permanent magnet motor, can move individually along straight or curved rails. The iTRAK can be used, for example, on packaging lines, in the medical industry (filling lines for IV bags), but also on assembly lines for machine construction. The combination of iTRAK technology with the Rockwell Automation integrated Architecture (programmable with Studio 5000 Logix Designer) lays the foundation for a new standard in dynamic linear transport solutions.

Flexible & user-programmable

In contrast to ‘rigid’ solutions using chains, V-belts and spindle drives, iTRAK provides a universal platform that is able to carry out any pattern of movement within wide margins.

The movement of each carriage can be programmed individually, bringing great flexibility. Switching to other products and/or another production sequence will present no problem whatsoever, since the iTRAK system is suitable for a wide range of applications in a diversity of production environments and industries. Apart from its flexibility, iTRAK can operate at speeds of up to 7 m/s, at a positioning accuracy (stops) of 0.05 mm. Accelerations of up to 10 g enable fast starts from a standing position, which makes it an extremely dynamic linear transport system, designed with energy-efficient linear motors using powerful magnets and advanced digital control.

The Italian based Cama Group, known globally for the cutting edge technology and reliability of its packaging systems for food and non-food industries, introduced a new cartoning machine based on iTRAK. The system is totally integrated with the Rockwell Automation hardware and software technology, selected by Cama to build the automation and control core of the machine. "Featuring 10% reduced floor space and an advanced control software system, the CL 175 uses less steel in its construction”, says Riccardo Panepinto, operations director at Cama Group. Further benefits to the end user include optimised format changeover, lower maintenance needs and energy savings. The automatic changeover doesn’t require manual intervention and is key to the machine performance improvement too.

Flexible expansion possibilities

Both horizontal and vertical transport lines can be assembled using iTRAK rail sections that are available in straight and curved (90°) versions in standard lengths of 400 mm. What’s more, the rail sections come with three different motor frame sizes (50, 100 and 150 mm) for various outputs.

Carriages are available in a standard versions and with customisation for specific applications. Customers can also design their own carriages if they chose to.

Power and control modules are included with the iTRAK system and are designed for global voltage inputs.rogramming is carried out using the Rockwell Automation Studio 5000 Logix Designer, whilst communications are enabled by EtherNet/IP.

- Rockwell to acquire ASEM

- Be at the leading EDGE

- Factories care about outcomes, not AI

- Flexible relay solution simplifies safety implementation

- Linear motion control system

- End-of-line packaging system

- Bottomley & Hadfield take on new roles at Rockwell

- A modular approach in manufacturing

- Rockwell Automation & Accenture Industry X.0 combine forces

- Versatile Machine-Guarding

- FIRST FASTBOX

- REAL TIME CUTTING MACHINE DATA

- HARMONIC CANCELLATION

- Integrated Motion Control

- Tailor Made For Automated Warehouses

- Number of Operators Reduced

- Prevents Potential Material Release

- Integrated or Standalone

- Improved Efficiency & Reduced Labour

- All components in one functional compact unit