|

Charlotte Stonestreet

Managing Editor |

Pick of the show

21 April 2016

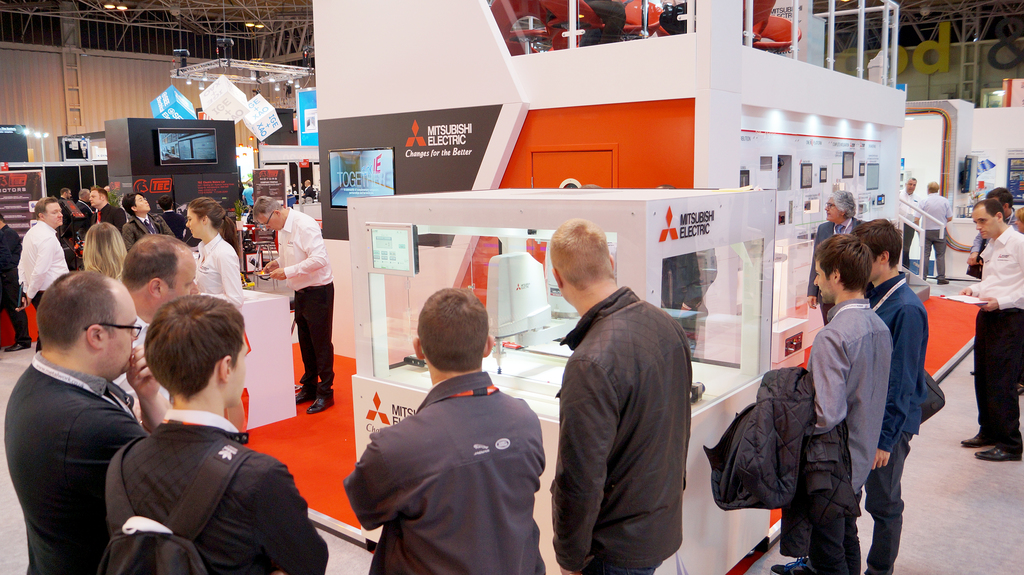

Mitsubishi’s range of dextrous robots was out in force at Drives & Controls 2016, along with an innovative pick-to-light demonstration that halved the time taken for assembly tasks.

Demonstrating various high-speed pick and place applications within confined spaces, MELFA robots showed how repeat tasks could easily be taken care of by compact, reliable robots. The robot feature that drew the most attention at the show however was the ability of an articulated arm robot to slow its work rate as a person came closer to it.

Demonstrating this feature in the ‘Robot Zone’ was a 15kg MELFA robot, around which proximity zones were shown using coloured carpet. Visitors could safely approach the robot, which had no physical guarding in front of it and the robot would switch to a creep speed as they entered the ‘amber zone’ and would stop entirely should the person enter the designated ‘red zone.’ If the person then withdrew, the robot would resume, initially at creep speed as the person moved out of the red zone and then at full speed as the person moved away from the amber zone.

In a working environment this type of smart interaction saves time and can improve safety. Many operations require the operator to interact with the process, for example loading or removing components and this system speeds up that process as there is no need to spend time opening and shutting traditional guarding systems.

Fully integrated automation and robotic solutions can offer significant quality and productivity benefits. The displays at the Drives & Controls show were designed to demonstrate both this and the capabilities of individual automation components such as PLCs, servo systems, HMIs and inverter drives with robots and the extra benefits that accrue when they are integrated into larger systems.

Chris Evans, marketing and operations group manager at Mitsubishi Electric – Automation Systems Division UK commented: “It was a very successful show for us measured purely on the positive interest we received and the number of leads it generated. The desire to invest in automation is certainly there in UK manufacturing industry.

“The robots and the ‘Poka Yoke’ pick-to-light demonstration definitely generated the most interest. The pick-to-light demonstration in particular showed how human assembly tasks could be sequenced and speeded-up by guiding operators to make accurate decisions more quickly – so we covered everything at the show from our fully automated ‘end to end’ production solutions, through improved person-to-robot interaction and using automation to help with repetitive manual tasks and minimise picking errors.”

- A pressing need for automation

- Inverter technology enables energy recovery

- Partnership secures substation refurbishment contract

- Wind(ings) of change

- Enhanced Clarity HMI

- Comprehensive service support

- Enhanced safety communications

- Production line efficiency drive

- Transparent Link Between Automation Components & PCs

- Mitsubishi Electric secures ESD certification for industrial robot portfolio

- No related articles listed