|

Charlotte Stonestreet

Managing Editor |

| Home> | AUTOMATION | >Robots | >Heavyweight robots |

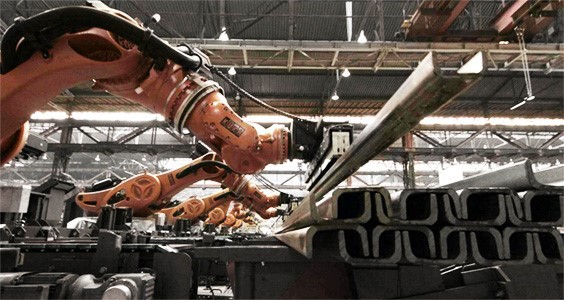

Heavyweight robots

16 June 2016

Mannstaedt, based in Troisdorf in the German state of North Rhine-Westphalia, produces tailor-made special profiles weighing up to 2.5t and up to 26m long. Six KUKA KR 1000 titan robots have been installed to handle the profiles.

Following delivery by conveyor, the special profiles are stacked by the robots in a space-saving manner. The stacks are then conveyed out of the robot station for shipment to the customers.

“The system is an absolute success. With simplified methods, we have made production easier and more flexible,” exclaims Marcus Haas, Plant Manager at Mannstaedt . The robots have enabled the company to significantly increase the flexibility of production, which is reflected directly in an enlarged range of products.

The success has prompted Mannstaedt to initiate new automation projects in the downstream production process.

- Balls to Gravity

- ROBOTS GIVE FASTER CELL TOOL CHANGE TIMES

- ROBOT FOR DELICATE ASSEMBLY

- NUMBER OF ROBOTS IN UK ON THE RISE

- The future is bright - The future is automation!

- High Demand For Grant

- More Capacity, Less Space

- FREEBIRD - THE THIRD DIMENSION

- PRECISION ROBOT CELL FOR THE PHARMACEUTICAL INDUSTRY

- ROBOT SALES REACH ALL TIME HIGH