|

Charlotte Stonestreet

Managing Editor |

Automation & Industry 4.0 technologies

24 August 2016

Motion plastics specialist, igus, will showcase a range of its latest automation solutions in line with industry 4.0 at this year’s Northern Manufacturing and Electronics (NME) event.

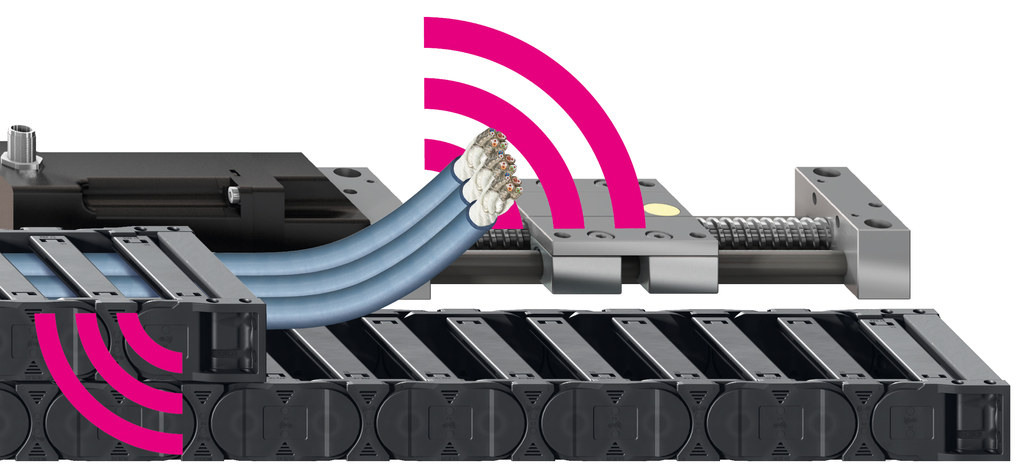

Visitors will see demonstrations of the new igus smart plastics that help enable machine and system builders open the door to Industry 4.0. The chainflex cable, energy chain and linear bearing products within the smart plastics range have embedded intelligence via the use of innovative sensing, monitoring and communication technologies.

Another new introduction to be demonstrated during NME is the igus online 3D printing service for wear-resistant prototypes and special parts. Engineers simply upload their STL file to an online configurator, check the component in the 360-degree view and specify measurements. Once the specific tribofilament is chosen, the parts can be ordered for printing and dispatch within 24-hours. Stand D44

- The 'enjoyneering' experience

- Self-built HT-3D printer

- New SLS material for electrostatically conductive wear-resistant parts

- World's first driven e-chain system

- Simplifies coating selection

- Versatile rapid machining

- igus evolves trapezoidal thread

- PTFE-free material for bearings

- CABLE STRIPPING IN HALF THE TIME

- Compact design solutions

- No related articles listed