|

Charlotte Stonestreet

Managing Editor |

| Home> | POWER TRANSMISSION | >Bearings | >Coming to a green space near you soon |

| Home> | MACHINE BUILDING & ENGINEERING | >Machinery Safety | >Coming to a green space near you soon |

| Home> | AUTOMATION | >Robots | >Coming to a green space near you soon |

Editor's Pick

Coming to a green space near you soon

05 May 2023

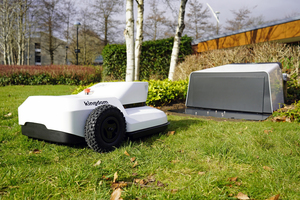

Charlotte Stonestreet visited Glasgow-based company Kingdom to find out how igus products are helping the company in the development of its innovative robotic lawnmowers

ROBOTIC MOWERS are nothing new, in fact it may surprise you to learn that they have been around since the 1960s. However, it is only in the last decade that the market has really taken off, with the units becoming a familiar sight in many a back garden. Unlike these domestic units, the machine developed by Kingdom is an industrial mower and can cover 10 x the area covered by a typical robotic mower.

Founded by CEO, Joan Kangro, in 2018 Kingdom Technologies aims to address issues facing the commercial lawn care sector in terms of workforce, environment and safety.

In common with many sectors, the commercial lawn care sector is experiencing workforce challenges. The often seasonal nature of the work and resulting employee retention/recruiting issues, combined with a general downturn in the number of staff available and increased wage demands, mean that staffing issues are cited as the number one reason that companies in the sector cannot grow their businesses.

When it comes to the environment, according to the US Environmental Protection Agency, a staggering 5% of the total air pollution in the US comes from IC engined lawn mowers. Noise pollution is also a factor, with IC engined mowers disturbing schools and offices. Added to this is that there are around 100,000 lawn mower injuries requiring hospital treatment each year in the US alone.

Commercial use suitability

Being electric, autonomous, and relatively safe, robotic lawnmowers offer a solution to these issues, however, according to Kangro, the models available today are not suited to commercial use. Much of this comes down to efficiency; they tend to cut in random patterns, potentially cutting the same patch of grass numerous times in one day, reducing the size of the area it is possible to cut.

Another issue with existing options is that they do not tend to be completely safe in public areas, for example, around people and pets. Installation can also be problematical, requiring a boundary cable that often breaks, drops current, and is not suitable for larger areas with, perhaps, multiple features that the mower needs to avoid.

The Kingdom mower cuts the grass in a human-like cutting pattern. Although the units are not much larger than competitor robots, simply having slightly bigger cutting discs and not going over the same piece for grass multiple times, the Kingdom mower can cover a far greater area. It features a multi-layer safety system whereby it is aware of obstacles and will stop before it bumps into them. The blades stop when the mower is close to humans and animals, making it much safer than alternative solutions. To achieve this the mower uses a combination of machine vision, and machine learning and LiDAR to detect and classify different obstacles.

The system has been designed specifically for simple set-up. Although still undergoing testing currently, Kingdom uses a web platform where users enter their address to access aerial photos, onto which they can then draw the boundaries the mower will be required to work within. This eliminates the need to install a physical boundary cable and makes it much easier to change the parameters should the need arise.

The positioning accuracy required to achieve the human-like pattern and cable-less setup is not possible using GPS technology, which gives an accuracy of a few meters. Kingdom uses a number of different technologies to enable the mower to be positioned with centimeter accuracy and is working on the programme that works out the optimum mowing pattern.

Human in the loop

While you could be forgiven for thinking Kingdom is well and truly established, as a start-up the company is still in the relatively early stages of development. Pilot projects have been running for just under three years using versions of the robot mower to cut around one million square meters of grass. Currently, the mowers are not fully autonomous, so the company offers support in the form of 24/7 'robot supervisors' who can remotely control a unit if necessary. This could be for example, if a robot detects an obstacle and for whatever reason cannot go around it, it will flag up the issue for human intervention. In some cases, it may be that the robot can perform the tasks autonomously but it still needs to be directly monitored, as is currently the case for some instances when the robot approaches the docking station and attaches to the recharging system.

This working model negates the years of testing that would be required otherwise, and has enabled Kingdom to achieve swift market entry. In development terms, it also helps Kingdom to determine the best way forward for the whole concept; the technology is available to detect and avoid an object, but whether this should always be what happens is a different matter, and having a human in the loop is often advantageous in determining optimum outcomes going forwards.

Maintenance-free

During the development of the mower, when it came to specifying bearings, the team at Kingdom was looking for a maintenance-free solution, avoiding lubricated ball bearings wherever possible. The company contacted igus Scotland sales engineer, Rob Dave, and together they came up with some problem solving solutions, some of which can be found in the cutting deck of the mower. In this situation, accuracy is of utmost importance since any deviation from specified tolerances can result in an uneven cut and dissatisfied customers. The precision of the igus bearing results in a deviation of <1mm in cut across the whole mower.

igus technology has also been used in the lift sensor mechanism whereby if the mower detects that it has been manually lifted up, it goes into safe mode and its motors are deactivated. Here, piston rings made of iglidur material are used to give a dry running, maintenance-free and reliable action in a very small package space.

Being battery powered, there is a need for the mower to regularly return to a charging station. igus bearings can be found in the opening and closing mechanism of the charging station housing; specifically igus drylin linear bearings, and dryspin leadscrew nut running on a standard dryspin screw. This provides reliable, fail-safe operation in all weathers and environments.

Since its inception, Kingdom has produced around 20 robot mowers, some of which have now been retired. The rollout has, says Kangro, been relatively slow so that an optimum design is achieved before the company starts scaling properly. As for the future at Kingdom, it's not constrained to the current robot mower by any means. The company is already looking at the possibility of producing units specifically for golf courses, which require a much closer cut. Consideration is also being given to a future where individuals no longer own their own lawnmowers or cut their own lawns, but book a nearby robot lawnmower to come and do the work for them via an app. Whether this vision comes to fruition anytime soon remains to be seen, but whatever the next developments at Kingdom, it seems certain that igus will continue to be a valuable and trusted partner.

Key Points

- Kingdom's robotic mower addresses workforce, environment and safety issue in the commercial lawn sector

- A human-like cutting pattern means the robot mower is highly efficient and can mow around 10 x the area of other units

- Maintenance-free igus technology is used on the cutting deck, lift sensor mechanism, and charging station door

- Adapter makes straight connectors angled

- Latest additions to linear guide system

- Sustainable plain bearing materials

- Smart bearings help prevent machine failure

- Small linear axis for large tasks

- Linear robots for cost-effective automation

- Med tech compatible material

- New SLS material for electrostatically conductive wear-resistant parts

- Cost-effective entry into automated logistics

- Cost-Effective Prototyping