|

Charlotte Stonestreet

Managing Editor |

| Home> | MACHINE BUILDING & ENGINEERING | >3D Printing & Prototyping | >Custom parts produced rapidly & economically |

Editor's Pick

Custom parts produced rapidly & economically

02 January 2017

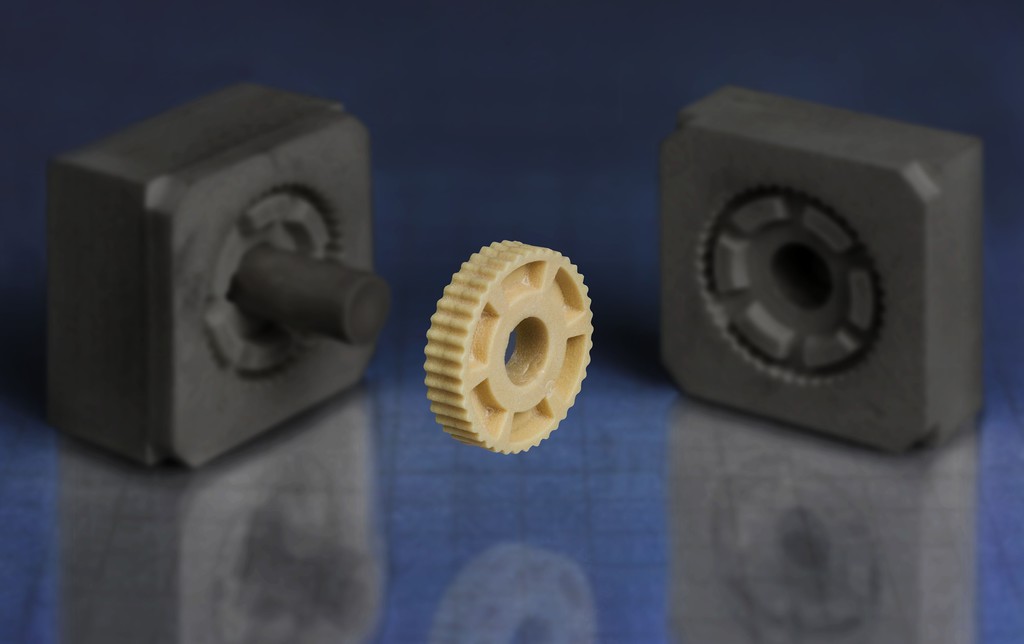

New from igus is a service to 3D print injection mould tools, enabling rapid and cost effective production of custom parts.

“Injection moulding tools, or moulds, usually manufactured from steel or aluminium for high volume production, can have relatively high costs, with longer lead times,” says Robert Dumayne, director, igus. “With 3D-printed plastic moulds, igus is providing more options for design engineers and manufacturers seeking a cost-saving alternative for prototyping or low volume production.”

For parts with simple geometries, the 3D printed injection moulds can be produced with short, lead times, using the SLS (selective laser sintering) printing process. The moulds are for use in existing injection moulding machines and are capable of withstanding these high temperatures for up to several hundred uses (depending on the iglidur material used). Injection moulded parts can then be produced using a wide range of proven and tribologically-optimised iglidur materials. Engineers can also still easily iterate on the design, quickly and inexpensively 3D printing new moulds.

- Energy & data connected in under an hour

- Low-cost automation support

- Adapter makes straight connectors angled

- Energy chain increases uptime for Jaguar Land Rover

- ESD-certified dress pack for industrial robots

- The 'enjoyneering' experience

- Plug-and-play energy chain

- igus makes e-chain recycling even easier

- Keeps energy chains on track

- igus receives ten thousandth readycable order from robotics company