|

Charlotte Stonestreet

Managing Editor |

| Home> | POWER TRANSMISSION | >Bearings | >Outstanding strength |

Outstanding strength

24 June 2013

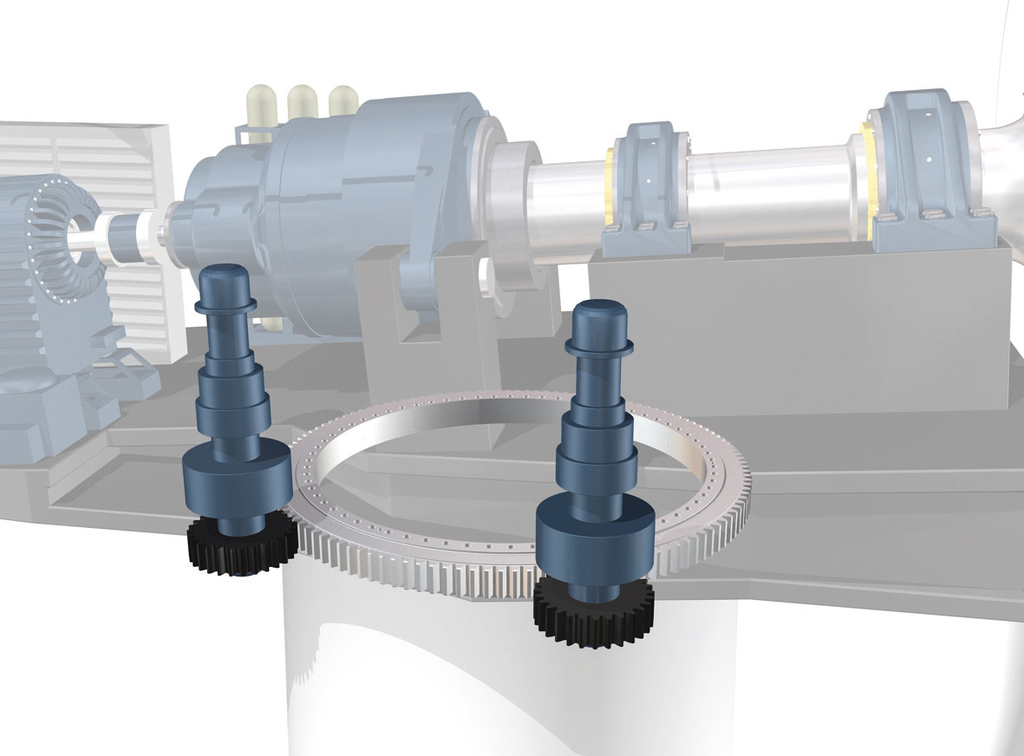

By working closely with the steel industry, bearings and condition monitoring specialist Schaeffler has co-developed a new, high strength quenched and tempered steel specifically for wind turbine slewing rings that are subjected to extreme loads during blade and tower adjustment.

The new material allows full tempering and quenching of the steel and, as a result, provides outstanding strength properties, even with large ring cross sections.

Zinc thermal spray surfaces, multi-layer painting and finished seal surfaces also provide the highest levels of reliability, bearing rating life and security against premature damage, such as fatigue of the raceways and surface corrosion.

Due to the material properties and the applied surface protection, the bearings are suitable for use in ambient temperatures down to -40˚C.

For wind tracking applications, Schaeffler currently develops and manufactures slewing rings with outside diameters up to 4,100mm. Due to their design, these slewing rings can transmit radial and axial forces, as well as tilting moments.

The bearings are designed as single row or double row, four-point contact bearings without gear teeth or with internal and/or external gear teeth. Their reliable function is a significant prerequisite for cost-effective operation of wind turbines.

- Schaeffler & Mitsubishi Electric announce global strategic partnership

- Precise levels of relubrication

- Pocket guide from Schaeffler

- Optimum lubrication for linear guides results in longer machine operating times & reduced maintenance

- Automatic relubrication

- Plummer block housed

- Eco-friendly packing system for large size bearings

- Angular measuring system

- Schaeffler presents electric motors ready for volume production

- Coatings prolong bearing life