|

Charlotte Stonestreet

Managing Editor |

| Home> | POWER TRANSMISSION | >Bearings | >Downtime & costs reduced |

Editor's Pick

Downtime & costs reduced

13 November 2013

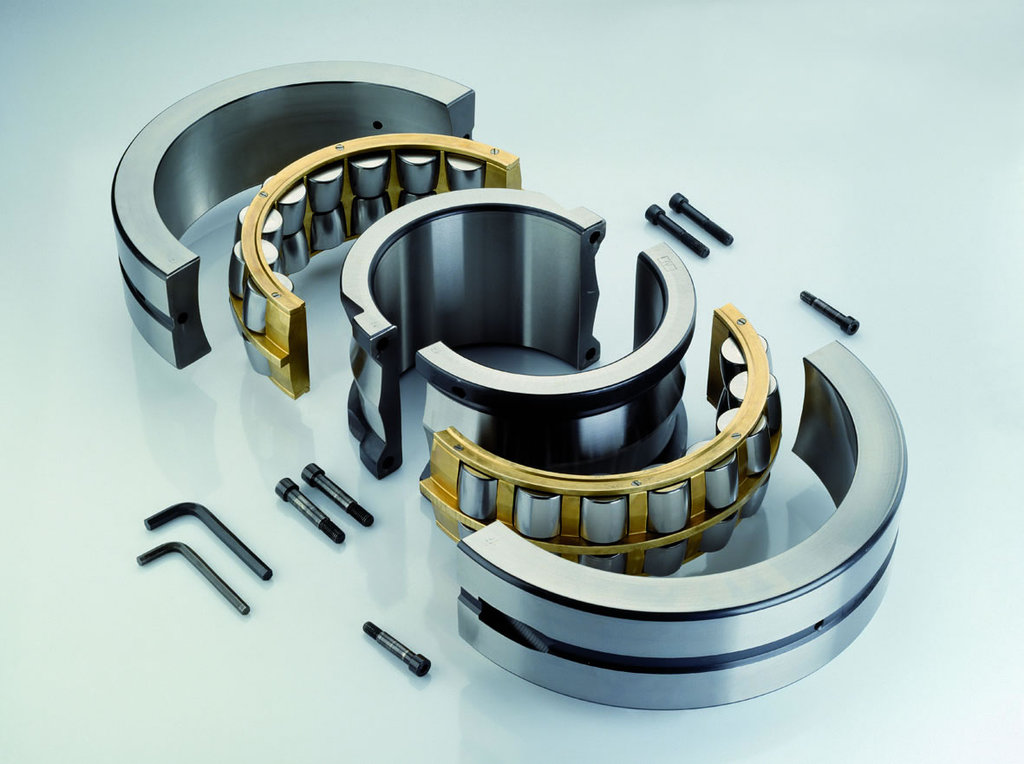

By replacing a solid spherical roller bearing on an exhaust gas fan with a split spherical roller bearing from Schaeffler, a chemical plant has saved €220,000.

The solid spherical roller bearing, which had an outside diameter of 230mm, needed replacing urgently. In the past, if the bearings were worn or damaged, the customer replaced these with similar solid (unsplit) spherical roller bearings. However, every time a bearing replacement took place, this resulted in 14 hours of downtime, which cost around €280,000. This figure not only included the cost of production downtime, but also the additional costs relating to labour, alignment of the shaft, crane hire and the costs of an additional replacement bearing.

By replacing the solid spherical roller bearing with a split spherical roller bearing from Schaeffler, the chemical plant reduced downtime to just three hours, with overall costs of €60,000. The costs of additional alignment, crane hire and a replacement bearing were not required this time. The customer therefore saved around €220,000 by using split spherical roller bearings.

Replacing damaged or worn parts on heavy machinery that requires regular servicing or maintenance can be a costly problem, particularly for companies in heavy industries such as mining, quarrying, oil and gas, paper, and steel production, where the value of capital equipment and production machinery is high.

The use of split spherical roller bearings reduces the time it takes to replace bearings, particularly in areas that are difficult to access such as shafts with multiple supports. In a split bearing, the inner ring, outer ring and roller-and-cage assembly are split into two halves that are clamped together using screws. A cylindrical bore provides direct mounting onto the shaft, which means the bearings typically offer high thrust loads and dynamically compensate for any misalignment. Also, by using a split version of the bearing, many stages of the mounting and dismounting process are omitted. This means that downtimes – and any associated costs – are reduced significantly.

- Effective unplanned downtime prevention

- SBTi validates Schaeffler Group's emissions targets

- SIM open days see rise in female attendees

- Innovations for all-electric & hybrid vehicles

- Closed loop engineering

- Makes IoT available in practice

- Linear profile rail system replacement

- Things It's Worth Bearing in Mind

- Schaefler Brakes World Record

- Former ambassador Dr Peter Wittig joins Schaeffler to head Global Affairs unit