|

Charlotte Stonestreet

Managing Editor |

| Home> | AUTOMATION | >Robots | >Plug & weld robot cell |

ARTICLE

Plug & weld robot cell

27 February 2014

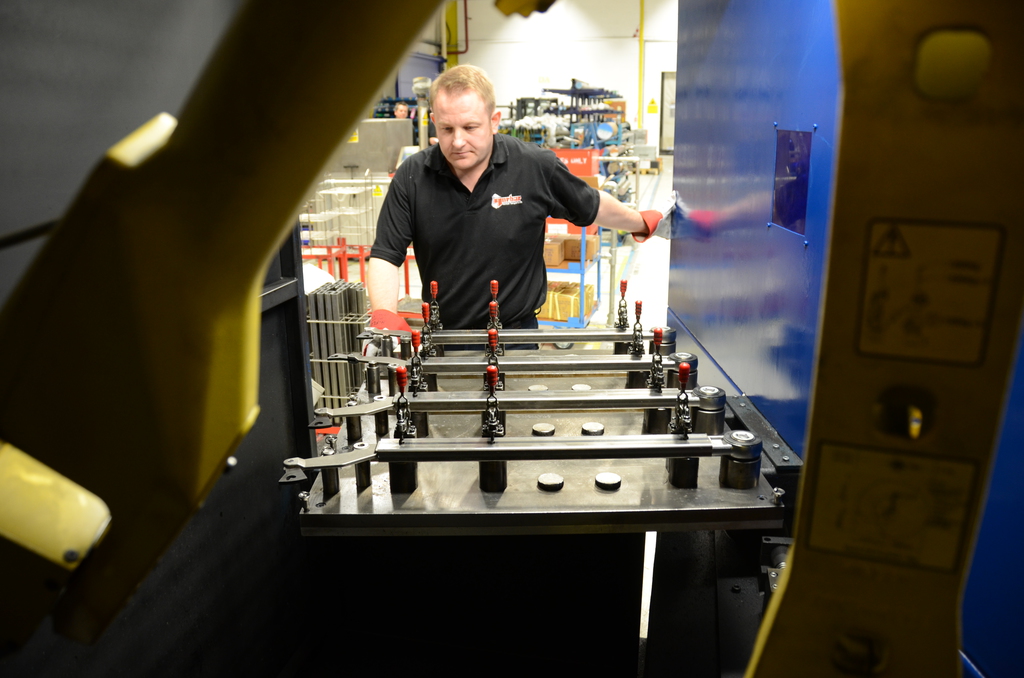

Norbar Torque Tools has upgraded its welding facility with a new robotic welding cell engineered by Cyber-weld. Providing increased capacity and quality improvements in a smaller footprint, the new system is based around a FANUC ARC Mate robot.

Cyber-weld designed what is essentially a 'plug and weld' robot cell comprising a FANUC ARC Mate six axes welding robot, an integrated MIG welding power source, turntable and fume extraction.

Requiring only power and gas supplies, the system was available for pre -production trials and commissioning within hours of its delivery.

MORE FROM THIS COMPANY

- Fanuc praised for changing perception of industrial automation

- Cobots increase productivity

- ROBOT FOR DELICATE ASSEMBLY

- Robots collaborate

- Extra reach for high speed applications

- FANUC to host manufacturing, automation & digital transformation open house

- Transforming manufacturing

- FANUC extends J L Goor partnership

- FANUC adds to compact industrial robot series

- Leading by example

RELATED ARTICLES

- Balls to Gravity

- ROBOTS GIVE FASTER CELL TOOL CHANGE TIMES

- ROBOT FOR DELICATE ASSEMBLY

- NUMBER OF ROBOTS IN UK ON THE RISE

- The future is bright - The future is automation!

- High Demand For Grant

- More Capacity, Less Space

- FREEBIRD - THE THIRD DIMENSION

- PRECISION ROBOT CELL FOR THE PHARMACEUTICAL INDUSTRY

- ROBOT SALES REACH ALL TIME HIGH

OTHER ARTICLES IN THIS SECTION