|

Charlotte Stonestreet

Managing Editor |

Editor's Pick

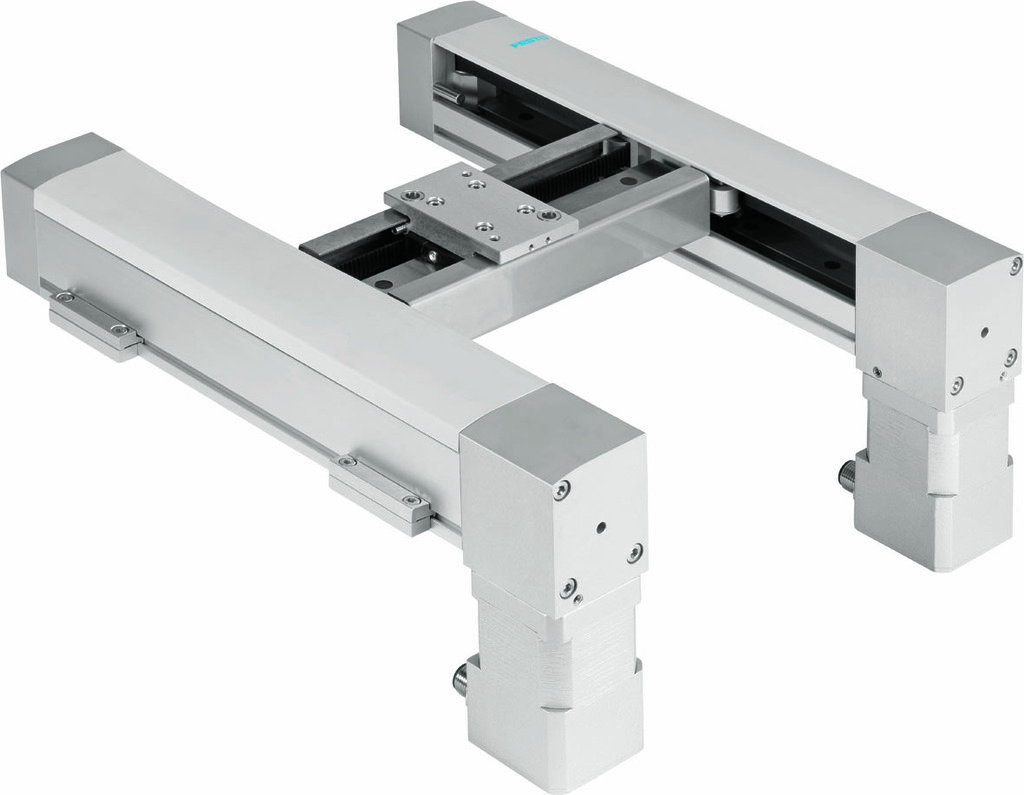

Compact gantry for precision positioning

02 April 2014

New from Festo is a compact gantry, the EXCM Mini H Handler, which offers precise, fast positioning. It is reported to be the world’s first production, off-the-shelf handling gantry to feature kinematic technology; this significantly reduces lifetime costs.

The new H Handler systems are attractively priced, while faster throughput, improved energy efficiency and reduced downtime combine to reduce operating expenses.

The EXCM Mini H Handler’s parallel kinematic system is energy efficient compared to traditional Cartesian positioning systems in which one motor must transport the weight of the other. Instead, two motors act directly on the load via a common recirculating tooth belt. By sharing the load in this way, the robotics can achieve higher dynamics, and EXCM realises positioning speeds of up to 0.5 m/s with less cost, energy usage and vibration.

The Mini H Handler’s closed-loop servo controller can drive the end effector rapidly and accurately to any X-Y co-ordinate position.

The Handlers start from just A4 size with a good ratio of working area to total footprint. Installation height is also minimised, as both motors lie in the same plane. With these compact dimensions, the EXCM Mini H Handlers are perfect for desktop applications, such as those found in electronics, light assembly, and medlab. Their robustness and reliability increases uptime; as neither motor moves, no energy chain is required, which eliminates drag and cable failure - traditionally the greatest causes of downtime.

The Mini H Handler range currently comprises two products; the EXCM-10 and the EXCM-30. The EXCM-10 offers its kinematic benefits in a basic package, while the EXCM-30 supports a higher payload of up to 3kg, and high precision, with a maximum acceleration of 10m/s2, maximum speed of 0.5m/s and repetition accuracy of ±0.05mm with ball bearing guidance. The gantries are available with six X-axis fixed stroke lengths up to 700mm and a Y-axis stroke up to 360mm.

- Electrical positioning systems made easy

- A toast to sustainability

- Focus on smarter automation

- Position transmitter

- Packaging system concepts

- Proportional valve use whitepaper

- Festo extends reach of VTUG and MPA-L valve terminals

- The opportunities offered by artificial intelligence

- Re-breather function

- Solve machine setting issues