|

Charlotte Stonestreet

Managing Editor |

ARTICLE

Simpler Machine Control Architecture

26 January 2015

Many machines today can be described as 'motion-centric', that is where motion is key to the function of the machine. Such machines will have a controller, usually a PLC, and drives for the motors or geared motors. The complete automation system for a motion-centric machine will often include I/O, visualisation, and one or more fieldbuses. A simple architecture with Lenze controllerbased automation offers machine designers high performance together with easy integration.

Controller-based automation is the name for architectures where a powerful central controller runs the operating system and motion programs. Outside the central controller other devices such as touchscreens and drives are 'dumb'. Controller-based architecture suits more complex machines, typically with 3 or more axes, and particularly where synchronisation or interpolation is needed.

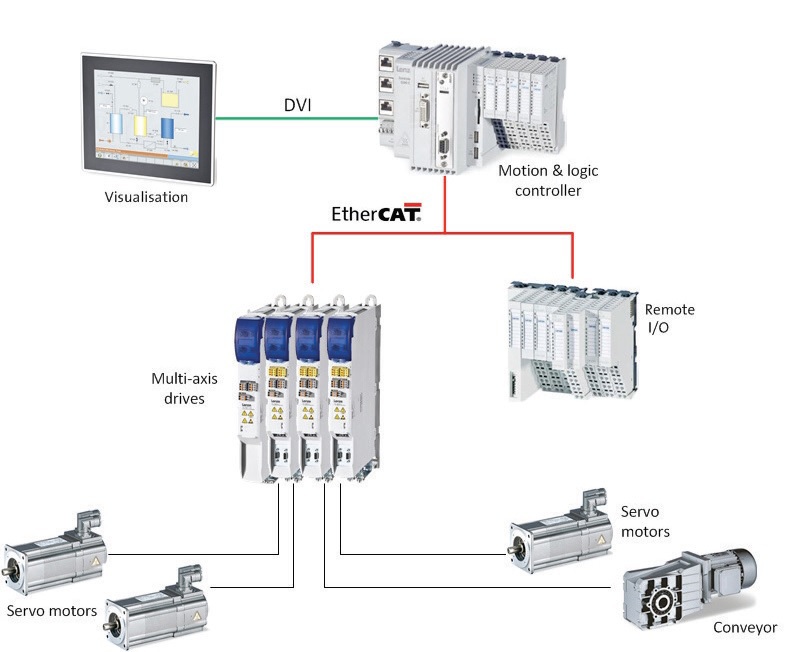

An example here is a typical topology to suit a pick and place machine with three servo axes and one further axis for conveyor feed. The PLC logic and motion control is done in a compact DIN rail mounted controller that has I/O slices plugged directly to the side.

Touchscreen visualisation is connected by a DVI link. An EtherCAT bus is used to connect to the multi-axis drives and also to a remote station of I/O. The drives are capable of running both synchronous servo motors and asynchronous 3-phase motors. Overall such a topology is simple to implement.

To add some detail, the controller would typically be running a virtual axis from which the X,Y & Z axes are synchronised. The controller gives a 1 μs time stamp and this together with a real-time bus such as EtherCAT gives the capability for both high speed and high precision.

Lenze use EtherCAT as standard for their 3200C controllers and multi-axis i700 drives as it is economic, readily available and reliable.

The controller-based automation concept is flexible and can be expanded. The central controller can be combined with the visualisation. Then PLC logic and motion control operates together with operator visualisation in one unit saving space in the panel. The choice between panel mounted controller with visualisation or a separate cabinet mounted controller depends largely on the layout of the machine.

Here the EtherCAT topology remains as before with a number of servo axes capable of high precision and interpolation. A separate logic bus can be added using a lower cost fieldbus such as CANopen which is included as standard in Lenze controllers and drives.

Particularly for applications such as registered cross cutters and flying saws combined with winding, such architectures that combine realtime precision with lower cost simple drive axes can be appropriate. A further addition to the automation system here is an upwards communication connection with Ethernet or PROFIBUS to a factory supervising computer and externally for remote maintenance.

Lenze have ready the controllers, visualisation, I/O and the drives that link together without problem interfaces and speed the machine design process.

MORE FROM THIS COMPANY

RELATED ARTICLES

- Robotics & Automation 2013

- Automation on the upswing

- Amendment to Commission Regulation (EC) No 640/2009

- Confidence returning to UK manufacturing technologies

- A national success story

- Automation: plan to succeed

- EPTDA expands in the Middle East & Africa

- Innovating for the recovery, innovating for the future

- A system-oriented approach to assessing energy efficiency

- tGARD IN ACTION

OTHER ARTICLES IN THIS SECTION