|

Charlotte Stonestreet

Managing Editor |

Twin PID loops

15 June 2015

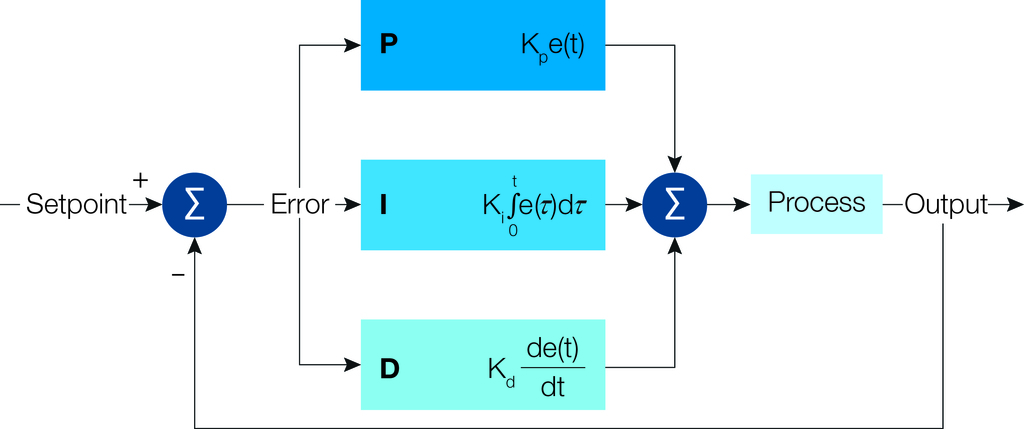

Two PID (proportional integral derivative) controllers, feature in the latest ABB drives, making it easier and less expensive to set up control loops to manage industrial processes.

The ABB drive contains two independent PID loops, which can be selected from digital inputs. The addition of the two loops means that instead of simply controlling the speed of the motor, the drive can command the motor to run at a speed that will allow the user to control any measured plant variable, such as pressure, flow, temperature, height, thickness or strain.

PID is useful when upgrading applications to save energy, as the drive can be tasked to undertake accurate control of a variable, such as pressure from a compressor, and only use the required energy to develop the required air pressure to run, for example, an industrial robot.

Having PID inside the drive means there is no need for an external PID controller, which can be expensive, or for a PLC, which can be complex. The drive can be tasked to control the item locally. Features like "sleep” can be employed to save energy and optimise performance.

The use of two PID loops allows the drive to be used in a cascade control arrangement in which there are two or more controllers. In this, one controller’s output drives the set point of another controller. This could be a level controller driving the set point of a flow controller to keep the level at its set point. In turn, the flow controller drives a valve to match the flow requested by the level controller.

Cascade control improves primary variable control which means it is less affected by disturbances and allows faster recovery from any such disturbances.

- ABB to invest $280m in European Robotics hub

- New drive for HVAC applications

- Advanced services

- Automation technologies

- Certified NEMA motor modifications

- Saves energy cooling costs

- VSD cuts saw stoppages

- ABB launches on-line tool for selecting MEPS compliant motors

- Giant syringe powered by ABB drive

- Diagnostics service