|

Charlotte Stonestreet

Managing Editor |

| Home> | DRIVES & MOTORS | >Variable Speed Drives | >Testing time cut by weeks |

Testing time cut by weeks

26 February 2015

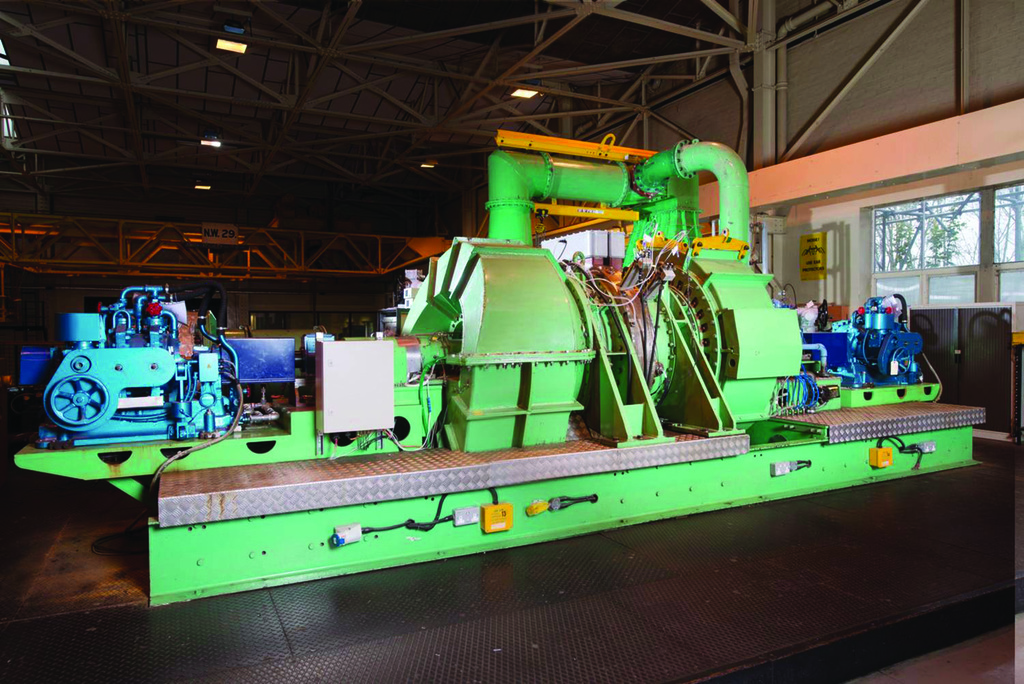

A major manufacturer of steam turbines has cut the time needed to change its test rig set-up from six weeks to a few hours following installation of an ABB variable speed drive

Alstom Power of Rugby tests 1/10th scale steam turbine blades in a large pressure vessel. The vessel uses a compressed mixture of air and refrigerant gas to simulate steam and tests the components at low and high pressures.

Speed control of the DC motor to achieve the different pressures was achieved by means of gearboxes. The major problem was the time needed to change over from the low pressure to the high pressure testing. Another challenge was the age of the DC motor, which, having been installed for some 50 years was proving costly to maintain.

Alstom asked three companies to tender for the contract to improve the application, with ABB system integrator Iconsys winning due to fast delivery schedule.

Iconsys supplied and installed a new 4 MVA transformer, a 3.1 MW water-cooled motor and a 3.1 MW ACS6000 medium voltage VSD. The installation involved removing the existing motor and altering the bed plate to fit the new motor.

Another aspect was modifying the incoming protection breaker. This originally had protection circuits for the liquid-cooled starter and needed to be modified so it could provide the required 3.1 MW for the motor. Iconsys installed all the cabling and supplied and installed a safety PLC to control the Motor.

- Award for diverse training course portfolio

- Eliminates gearbox failure

- Injection moulding energy costs cut

- Energy Saving

- VSD cuts baler energy costs

- More intuitive cobot programming

- 3D inspection robot

- Control system cuts costs & boosts production

- ABB launches Drives Solutions Team

- Reversing rougher powered

- PUMPED UP PERFORMANCE

- SOFT STARTER OR VARIABLE SPEED DRIVE?

- Jeans With Less Energy

- Enhanced to Withstand Tough Environments

- Savings From Improved Torque Ratio & Efficiency

- Modular VSD

- ENERGY SAVING: AN OLD MESSAGE WITH NEW PROMISE

- Updated installation guide for power drive systems

- UK drives manufacturer seals global automation deal

- WEG motors & drives power high-efficiency air blowers