|

Charlotte Stonestreet

Managing Editor |

| Home> | AUTOMATION | >Robots | >Shelf-ready case loading |

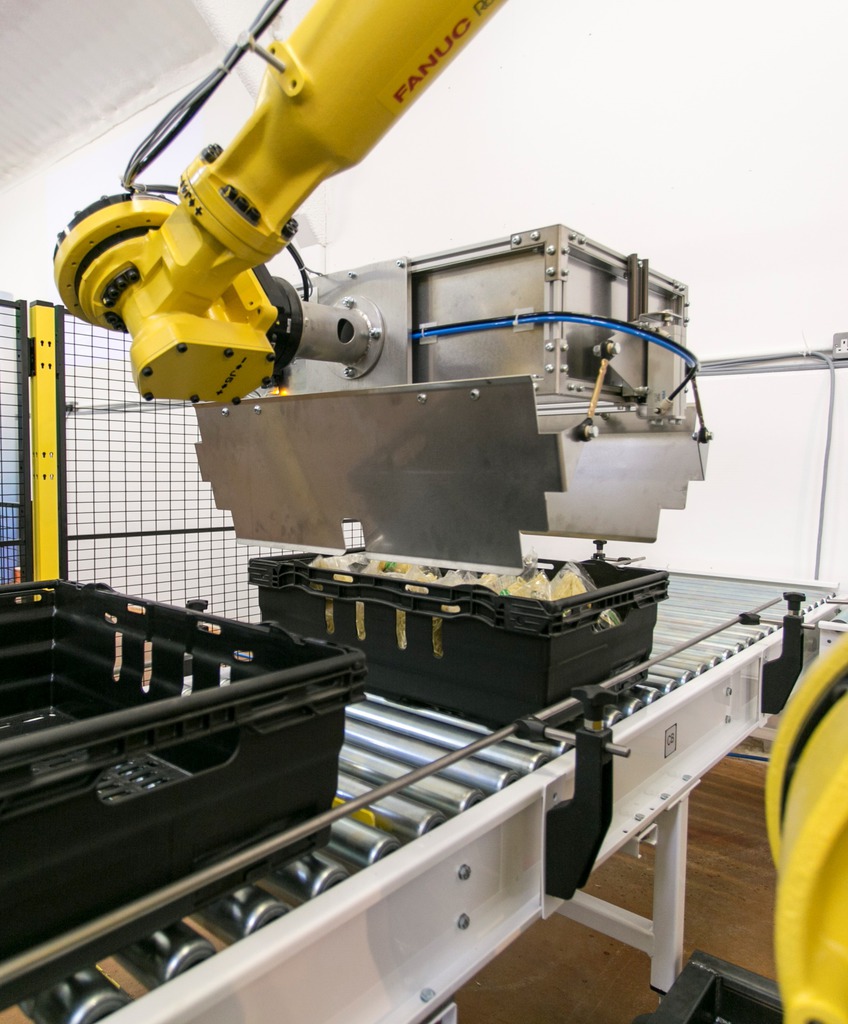

Shelf-ready case loading

14 July 2015

FANUC UK has expanded its M-710iC series of industrial robots with the M-710iC/45M, a mid-sized, high speed robot with a long reach. With a 45kg payload and reach of over 2.6m, the M-710iC/45M offers a smaller and more cost effective alternative to many large palletising robots – potentially in the order of 12%-15% reduction in robot price.

The robot’s application space also extends to product handling and pick and place tasks, where its long reach renders it the ideal choice for produce collation functions bridging between out-feed and packing conveyors.

"Historically, there has always been a tradeoff between payload and reach, with packaging and processing industry users having to go for a bigger robot if they wanted long reach capabilities. The M-710iC/45M opens up new opportunities for more efficient pick and place or palletising tasks, with its extended reach and stack height capability," says John Rainer, regional sales manager at FANUC UK.

"In conjunction with high speed operation, this enables one single M-710iC/45M to service up to six euro pallets for highest return on investment and fastest payback,and as with all FANUC robots can be equipped with line tracking and vision for on-the-fly picking and product identification.”

At PPMA 2015 the new M-710iC/45M robot will collate shingle-fed produce packs and load them into a shelf-ready carton. The system will feature a unique tilted end effector handling packs of noodles. To show how packs can be taken from a horizontal to a vertical shelf-ready position, the packs will shoot off the end of a conveyor into the end effector which lowers until several packs are stacked one on top of the other. The end effector then moves to a horizontal position, presenting the packs in an upright collation for loading into a box or shelf-ready tray.

Palletising and depalletising are also expected to be massive application areas for the M-710iC/45M, owing to the space and cost saving potential that arises from a medium payload coupled with extended reach and high cycle speeds (1350/hour). In designing the M-710iC/45M, FANUC’s engineers have built a six-axis, IP67 certified, articulated arm with best in class reach and the ability to stack pallets as high as 1.89m - all on a compact 535 x 550mm footprint. Floor, wall, angle and ceiling mounting options add to its flexibility. Stand C50

- FANUC celebrates student success in Industrial Robotics contest finals

- Design tips to futureproof your production

- Manufacturers must prioritise TCO when specifying automation

- Real-world robotic innovations

- Arc welding robot with long reach

- Robots collaborate

- Robots net benefits for fish supply chain

- FANUC groups & rebrands

- Explosion-proof collaborative paint robot

- Looking for more insight into factory floor performance?

- Balls to Gravity

- ROBOTS GIVE FASTER CELL TOOL CHANGE TIMES

- ROBOT FOR DELICATE ASSEMBLY

- NUMBER OF ROBOTS IN UK ON THE RISE

- The future is bright - The future is automation!

- High Demand For Grant

- More Capacity, Less Space

- FREEBIRD - THE THIRD DIMENSION

- PRECISION ROBOT CELL FOR THE PHARMACEUTICAL INDUSTRY

- ROBOT SALES REACH ALL TIME HIGH