|

Charlotte Stonestreet

Managing Editor |

| Home> | AUTOMATION | >Networks | >Big data solutions |

| Home> | AUTOMATION | >Robots | >Big data solutions |

| Home> | CONTROLS | >Systems | >Big data solutions |

Big data solutions

21 July 2015

At PPMA Omron will give original equipment manufacturers (OEMs) and integrators a real insight into new developments in integrated control, high-speed robotics, and how real-time data interchange between production-line operations and enterprise-wide IT systems can meet Industry 4.0 expectations.

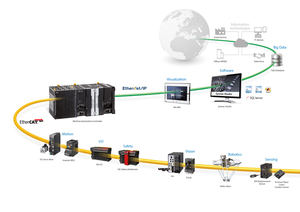

"Over the last 12 months the term Industry 4.0 has worked its way through the entire supply chain. As automation components grow in intelligence, the demand for ‘big data’ integration between the factory shop floor and top floor has also dramatically increased: linking of individual pieces of line equipment with enterprise-level databases in two-way real-time communication,” explains Dan Rossek, marketing manager, Omron.

On show, Omron’s latest control platform Sysmac, can create, integrate and act on this information at high speed, making best use of the data made visible by the machine and the information transferred to and from higher-level IT systems. This type of radical approach to production, already familiar in sectors such as the automotive industry, promises real benefits for flexible food and drink operations where a single line can accommodate many variants of the same of product without the need for a changeover from one batch to another.

Experts will show how seamless integration on the open Sysmac automation platform can cut lead times for machine builders, while allowing them and end users to keep their technology options open.

With the addition of the recently launched NX7 and NJ1 controllers, the Sysmac platform is suitable for a wide range of automation solutions from machines with either a low number of axes or none at all through to solutions for cutting-edge, advanced production systems.

"Machine builders and their customers are looking for ‘plug and play’ integration of automation technologies,” says Automation Product marketing manager, Barry Graham.

"Omron’s use of a single Integrated Development Environment for software configuration plus flexibility in programming languages means that software development times reduced dramatically,” says Graham. "Our goal would be to halve them, which would represent a massive cost saving for machine builders.”

Rounding up this year’s showcase, Sysmac Studio will be used to operate Omron’s latest Delta style robot. Machine builders will see how the software integrates machine control, vision, HMI and safety to develop reliable, cost-effective and efficient robot-based packaging systems. Stand B34

- OMRON appoints Reeco Automation cobot solution partner

- OMRON invests in Taiwanese collaborative robot company

- Omron debut world’s fastest and first 4 arm Delta robot

- Versatile & compact

- Versatile general-purpose inverter

- Big Data boosts production efficiency for manufacturers

- Pressure sensors for industrial control and safety applications

- Behind the curtain of automated inspection

- Robots speed up production of Covid-19 tests

- Cobot palletising solution