|

Charlotte Stonestreet

Managing Editor |

| Home> | AUTOMATION | >Equipment | >Auto clamping head |

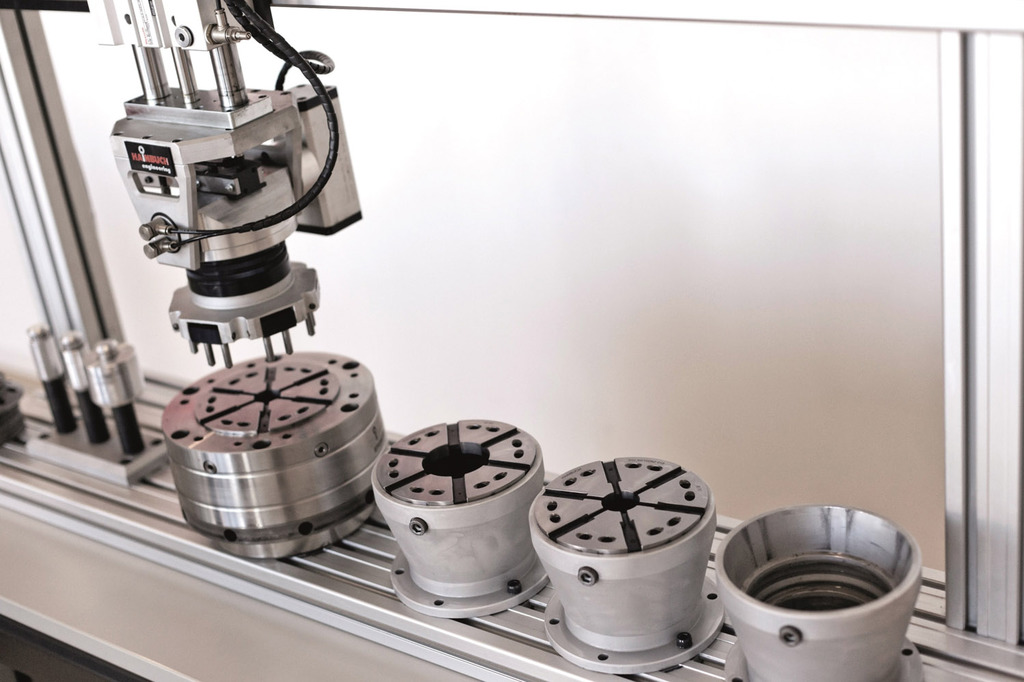

Auto clamping head

18 October 2015

To deal with small batch sizes, more variants and and greater time pressures, workholding specialist Hainbuch has developed an automation solution said to make the end user more productive, more independent and more flexible.

The stocking and changing station is placed on the workpiece feeder belt of a vertical lathe. To setup the system, the spindle passes with the chuck over the combination of clamping head and end-stop to be changed and it is swapped completely and reliably within seconds by a pneumatic pulse. The workpiece to be clamped is then directly grabbed from the next changing station and clamped. The innovative design demands no additional automation.

This new automation solution is said to be ideal for lower batch sizes or multiple part variants and it can enable operator free production over three shifts.

- Eagle Has Landed Exhaust Business

- Infra-Red Drying System

- INTELLIGENT FEED

- Modified Atmosphere Sandwich Packing

- Precision Fluid Dispensing

- Rockwell Automation expands Midrange system portfolio

- Jet dispensing system offers speed & accuracy

- Mitsubishi to host food & beverage conference

- Precise, repeatable & energy efficient

- LED line & bar illumination