|

Charlotte Stonestreet

Managing Editor |

| Home> | IIot & Smart Technology | >Industry 4.0 | >Intelligent interlocks |

| Home> | MACHINE BUILDING & ENGINEERING | >Machinery Safety | >Intelligent interlocks |

Editor's Pick

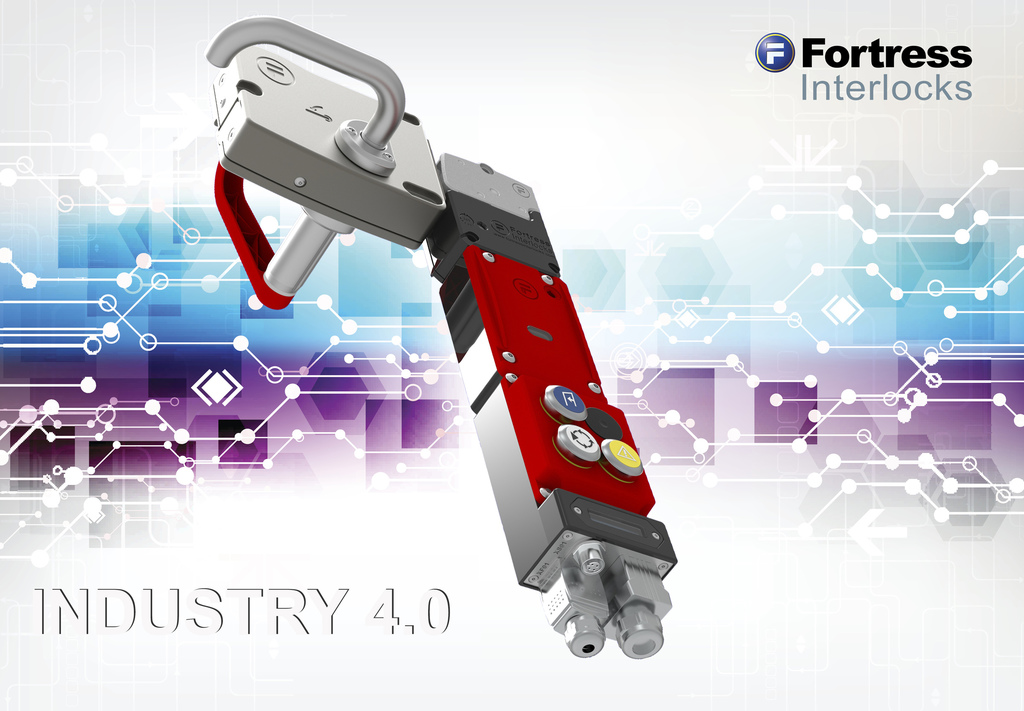

Intelligent interlocks

24 April 2017

With Industry 4.0 developing afoot, and collaborative robots and the automation of tasks previously manually carried out reducing the need for traditional machine guarding while increasing the need for smart interlocks, Malcolm Sharp, MD of Fortress' Australian operations, discusses how the company is facing these challenges.

"As the importance of data increases, we know that our products will be required to feedback through extensive, potentially global, data networks," he says. "We are already moving in this direction, with recent installations utilising our network-enabled gate switches designed to operate on safety networks."

"Two years ago Fortress launched an online configurator, enabling customers to create complex safety products from our wide range of modules and components. There are more than 4.9 billion potential configurations that could be created and since its introduction over 10,000 unique configurations have been created. Five years ago, such a configurator was unimaginable."

- New interlocks & communications modules

- Interlocks get TÜV SÜD certification

- Customised as standard

- Industrial Ethernet added

- Fortress appoints Underwoods sole UK distributor

- Compact safety key switch

- Interlock range configurator

- Ethernet added to interlocks

- IP69K-rated interlocks

- Easy safety switch fitting