|

Charlotte Stonestreet

Managing Editor |

Torque limiters for packaging industry

16 August 2017

Torque limiters ensure the reliable protection of people and materials in packaging machines and filling lines.

They disconnect the input and output within seconds, and therefore prevent expensive damage. For system operators, this means simple recommissioning, increased machine availability and minimised reject costs. mayr power transmission has developed a wide spectrum of torque limiters so that the clutches are optimally adapted to the respective application.

Natural mineral water is the most popular non-alcoholic cold beverage in Germany, with a consumption of 148.2 litres (2016) per capita. Sales continue to rise, and in 2016 had already reached more than 11.3 billion litres. Intelligent, high-performance machines are permanently in operation in order to efficiently and quickly fill and package these large quantities of mineral water bottles. During this process, PET mineral water bottles are often grouped into packs of six or twelve bottles and wrapped in film, in the same way as cartons or cans containing other beverages.

So that all processes run smoothly in such film wrapping machines, many manufacturers and users rely on mechanical torque limiters by mayr power transmission. In these packaging machines, the products are wrapped in a film in the initial step, with so-called film wrappers or arms guiding the film around the product. Should the arms impact an object while wrapping, for example, a bottle which has toppled overdue to a filling faults, then the torque limiters interrupt the torque transmission within seconds. In this way, such torque limiters reliably protect the drives in these arms against damage due to overload. The system can therefore be quickly put back into operation without having to replace or repair parts.

Why torque limiters are essential

Despite the electronic monitoring functions of the machine control unit, for example motor current measurement, mechanical torque limiters such as the EAS-Compact by mayr power transmission remain vital components in the packaging industry, because although the electronic motor current measurement recognises faults and errors, it can only disconnect the input. As a result, it is too slow to prevent collisions at the continuously-rising production speeds. Mechanical torque limiters, on the other hand, can open the drive line and decouple masses within fractions of a second, thus reliably preventing expensive damage. Furthermore, through opening of the drive line, for example, the removal of a jammed and possibly damaged product is therefore easy to execute and uncomplicated. As a result, processes do not have to be reversed and products do not necessarily have to be thrown away. Torque limiters therefore simplify recommissioning, increase machine availability and help to minimise reject costs.

The right clutch for every application

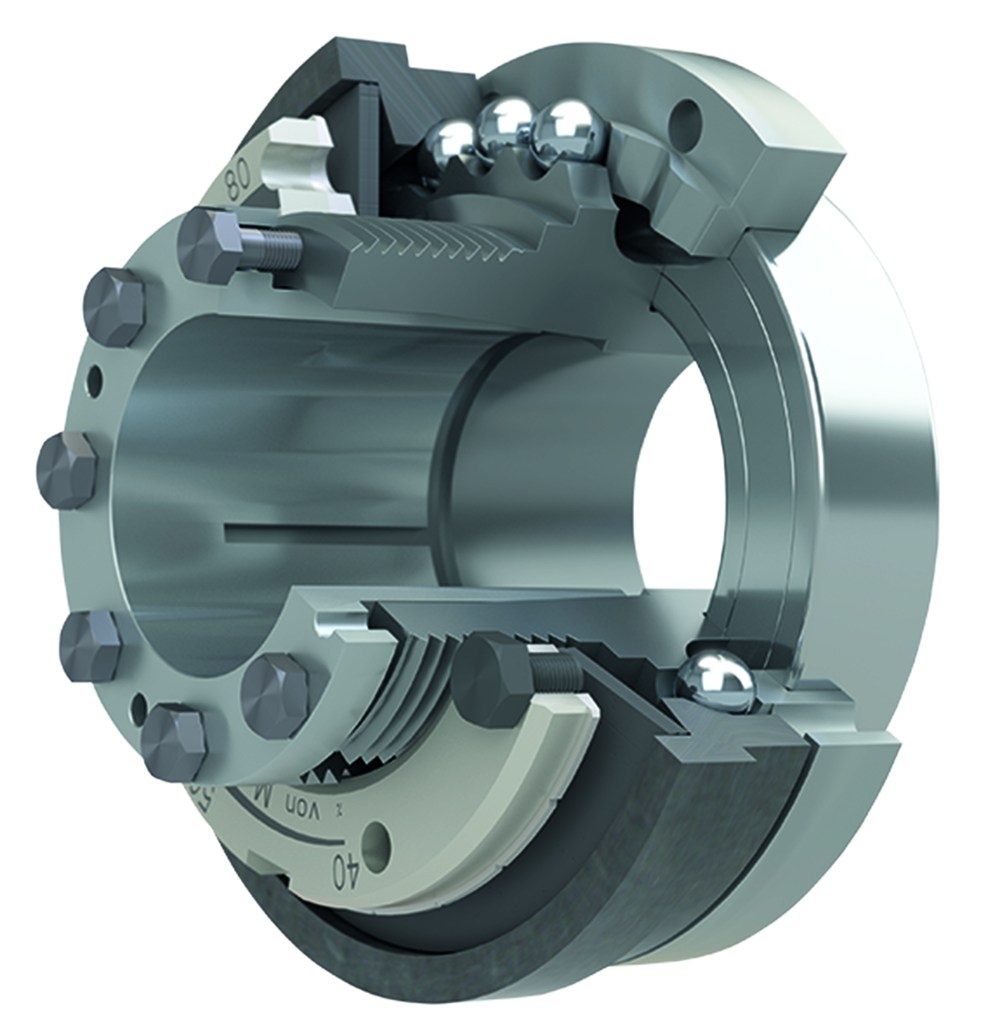

mayr power transmission provides a versatile product portfolio of torque limiters for various process steps in the food and packaging industry. The EAS-Compact torque limiters belong to the load disconnecting clutches, and these transfer the torque through positive locking. The torque itself is generated through the pre-tensioning of cup springs. Load-disconnecting torque limiters disconnect the input and output in case of overload or collision, i.e. they interrupt the torque or force transmission. EAS-Compact clutches in ratchetting design are immediately ready for operation after elimination of the fault. Ratchetting clutches re-engage automatically, for example every 15 degrees, or at a defined position depending on the application, and synchronous clutches after 360 degrees.

As a result, the latter are often the preferred choice in the case of rotary tables. For example, EAS-Compact synchronous clutches are used in a filling line for cream cheese. They are respectively positioned at the drive in the centre of the rotary table, and the table top holding the cream cheese containers to be filled rotates. In case of overload - for example, if too many empty containers are positioned and the table jams, then the torque limiter disengages. It automatically re-engages after one complete revolution, in exactly the same position.

Benefits of disengaging clutches

On the contrary, torque limiters with a disengaging design disconnect completely and almost residual torque-free. They remain in this disconnected position until they are manually re-engaged or re-engaged using a device. Disengaging torque limiters are therefore particularly suitable for high-speed drives or drives with large mass moments of inertia. Here, the stored rotational energy can slow down freely in case of a collision.

For applications in which long run-out times are required and where the drive is also difficult to access, mayr power transmission provides an ideal solution with the robust EAS-reverse torque limiters. These clutches automatically re-engage simply through slow reverse rotation at a speed of < 10rpm, without the use of pneumatics or hydraulics.

Protected against wet and dirty conditions

The EAS torque limiters by mayr power transmission can be adjusted extremely accurately and work with high repeat accuracy. During fault-free operation, they transmit the torque backlash-free and therefore ensure a high service life and minimal wear. The company provides special designs and constructional designs made, for example, from stainless steel with seals or a housing, for fields of application such as the food industry, where wet conditions and cleaning liquids are part of the daily ambient conditions.

Application cases for load holding clutches

Load holding torque limiters such as ROBA-slip hubs come into to use in filling or packing machines in which products are moved at an angle or vertically, and which must not crash even in case of overload. These torque limiters transmit the torque via frictional locking, i.e. via friction linings which are pre-tensioned using cup springs. The more the cup spring is compressed by the adjustment nut, the higher are the transmittable torques. In case of overload, the flange slips through with the drive element against the resistance of the friction linings. The clutch therefore does not interrupt the torque transmission, but instead holds the load with a set torque; the products do not drop uncontrollably. In the case of ROBA-slip hubs, torques can be steplessly and accurately adjusted to the respective operating conditions via a scale on the adjustment nut. These are also robust, and protected against the penetration of cleaning liquids and other liquids thanks to their enclosed construction. Depending on the requirements, ROBA slip hubs can also be designed with corrosion protection.

Complete solutions from a single source

Torque limiters provide effective protection for sensitive machine elements or products. However, in order to reliably protect against overload damage, a torque limiter must optimally match the respective application. As a worldwide-leading manufacturer, mayr power transmission therefore provides a wide, sophisticated product range. This renowned family-run company can call on decades of experience, extensive expertise in development and design and rely on the most modern testing possibilities. And besides torque limiters, mayr power transmission also develops and manufactures backlash-free and high-performance shaft couplings, because in many applications, a combination of a shaft coupling and torque-limiting safety clutch are used.

The portfolio of shaft couplings is just as extensive and includes various elastomer, steel bellows and disk pack couplings – each in diverse designs. mayr power transmission stands for complete solutions, and provides know-how and service from a single source.