|

Charlotte Stonestreet

Managing Editor |

EPLAN Smart Wiring to simplify control cabinet wiring

03 January 2018

Wiring a control cabinet requires a lot of time and expertise, however leading CAE software provider EPLAN has unveiled EPLAN Smart Wiring.

Smart Wiring visualises control cabinet wiring and provides the necessary production data digitally which completely eliminates the need to work from schematic diagrams when wiring control panels – a time-consuming and error-prone process that requires a great deal of knowhow, as research has shown that 43% of all design time is spent wiring a cabinet!

A key benefit of EPLAN Smart Wiring is that it memorises previously used control system elements, which are then available whenever they are needed for future use. This enables engineers to benefit from substantial time-savings, especially for last-minute changes, because the software also handles the frequently complex task of project comparison.

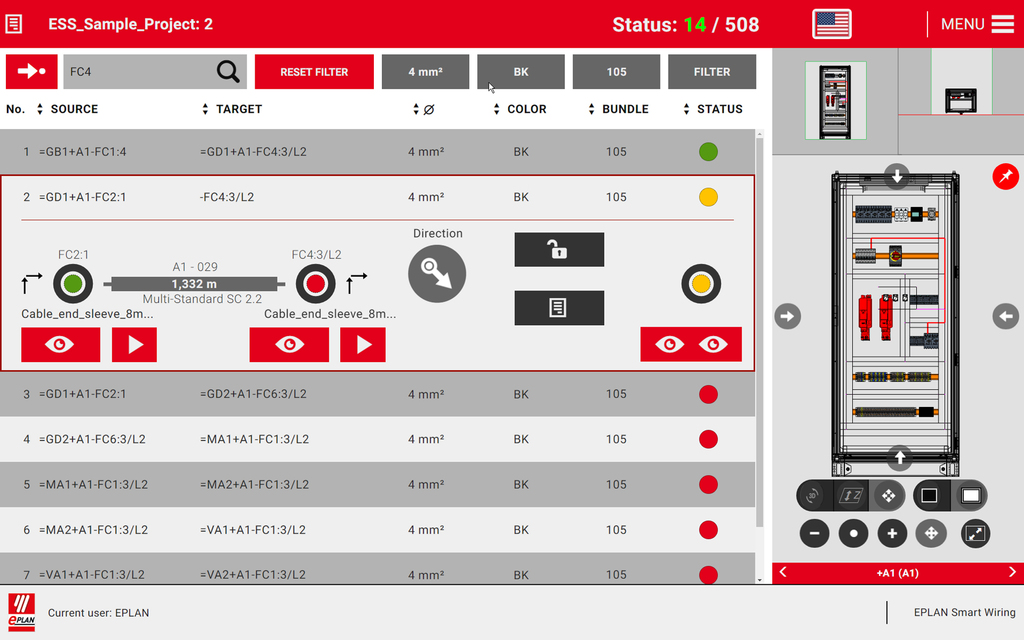

Whether it’s the source/target description, terminal point handling, cross sections, colour, wire length, end procedures or exact cable routing, the software provides a visual representation together with the necessary wiring information and engineering data for mounting and assembly within the control cabinet.

EPLAN Smart Wiring refers to the virtual model’s 3D-layout in EPLAN Pro Panel. Yet the new application can be utilised to enhance productivity even without a 3D layout.

The software has been design with simplicity and ease of use in mind. It offers step-by-step directions for the user, and through its clearly designed menu, it describes every single connection. This information is augmented with the equipment visualisation, including terminal points and the planned cable routing for the wires within the control cabinet.

In addition, the software also provides information about the required wire diameter, the colour to be used and the defined terminal point handling such as crimped or ultrasonic welding. Bundle affiliation is also shown clearly, which means that every connection as well as every working step, is clearly understandable and transparent.

As soon as a connection is completely wired, it’s shown in green. This is tremendously helpful if several shifts are necessary to complete the work: colleagues can start wiring exactly where their predecessors left off.

For further information visit www.eplan.co.uk

- The future’s bright, the future’s CAE

- EPLAN launches range of value-added products

- Hot-wired software

- Significant time savings for production operations

- Automation could deliver time savings of up to 25% says new study

- EPLAN to hold Industry 4.0 event

- EPLAN launches direct interface with Siemens TIA Portal

- Upgrade to CAE

- Schematics from the cloud

- What panel builders really want!

- No related articles listed