|

Charlotte Stonestreet

Managing Editor |

| Home> | MACHINE BUILDING & ENGINEERING | >Materials & Components | >Flame and thermal barrier passes UL 2596 torch and grit test |

Flame and thermal barrier passes UL 2596 torch and grit test

28 August 2025

TECHNOLOGY LEADER in thermal protection systems (TPS), Blueshift’s AeroZero Flame and Thermal Barrier (AZ-FTB) material has become one of the first thin profile TPS to pass and complete all 10 cycles of the UL 2596 Torch and Grit Test (TaG). Therefore, proving its market-leading performance in helping to mitigate the risk of thermal runaway in electrically powered aerospace applications.

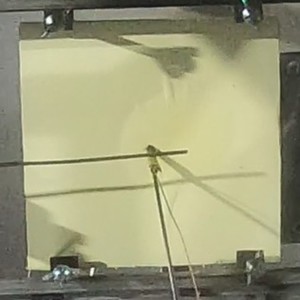

UL 2596 Test Method for Thermal and Mechanical Performance of Battery Enclosure Materials, Torch and Grit Test (TaG), is designed to provide a standardised approach for assessing the impact of explosions on electric battery enclosures. The TaG exam involves the exposure of an alternating pattern of flame (~15 seconds) and alumina ejecta (~5 seconds) onto a material sample. The twenty second alternating cycles are repeated up to 10 times, after which the material is said to have passed. The test is designed to prove the performance and durability of battery materials against the extreme temperatures and mechanical abrasion can rapidly cause failure within a battery system during a thermal runaway event.

Blueshift’s AeroZero Flame and Thermal Barrier (AZ-FTB) successfully passed all 10 cycles of the TaG test, proving resilient against high-intensity flame and grit cycles at temperatures reaching 1200°C and power levels of 3 kW. Despite its light weight and thin profile, no breaches or material failures were observed in all samples tested, highlighting the material’s exceptional resistance to extreme thermal runaway events.

Dr Lawino Kagumba, VP applications and research of Blueshift, reports that this reinforces Blueshift as a disrupter in the advanced material sector for electric aircraft and aerospace industries: “This marks a significant accomplishment for Blueshift as one of the first companies to produce a thin profile and light weight material capable of withstanding all 10 cycles of the challenging UL Torch and Grit test. This is a testament to our material’s unique capabilities and its potential to transform how design engineers approach battery module design.”

The tests were performed at UL Solutions’ Northbrook, Illinois facility following a demand for safer, more resilient battery systems.

- ARE YOU READY FOR…THE INTERNET OF THINGS?

- Machinery Safety Alliance announces 2014 Seminar programme

- Soft Robotics announces partnership with FANUC

- IET announces new chief executive and secretary

- Drive your energy strategy with data

- UK manufacturers face historic need for automation

- Bespoke apprenticeship addresses automation skills shortage

- Robot dog joins BMW Hams Hall team

- £365m funding announced for new UK aerospace R&D projects

- When robots and saws take over the night shift