|

Charlotte Stonestreet

Managing Editor |

| Home> | AUTOMATION | >Condition Monitoring | >Reliability gets connected |

| Home> | IIot & Smart Technology | >Connectivity | >Reliability gets connected |

Reliability gets connected

19 December 2022

CDA talks to Charly Achter, product manager at Fluke Reliability, about the benefits to be gained from a connected condition monitoring strategy

CDA: HOW does a condition monitoring program enable condition-based maintenance?

Charly Achter: Condition-based maintenance is one of four basic maintenance strategies on the market. The other three include the firefighting strategy – run-to-failure maintenance – as well preventive, or time-based maintenance, and finally predictive maintenance, or risk-based, as some think of it. All these strategies are valid. They are the baseline that you must select from for each piece of equipment.

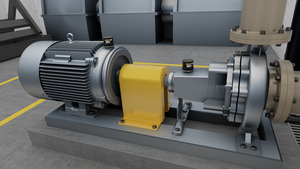

Many people want to move toward condition-based maintenance because it lets you make repairs when the asset actually needs them, instead of letting a machine break or performing maintenance from a calendar. To do this, you need to establish a condition monitoring program with sensors or handheld tools to collect regular data from your assets. Then you can monitor this data over time. By watching changes of the data, you decide whether something is broken or if the machine needs more analysis. This is how you get to condition-based maintenance.

CDA: What are the benefits that come with having a fully comprehensive maintenance strategy?

CA: There are three big benefits to having a comprehensive maintenance strategy: increased safety, reduced downtime, and saving money. Having a fully comprehensive maintenance strategy means that you really look at your assets and think about which assets are critical, which are less critical, and which assets are non-critical. And you really split your machines into these categories and then go into the different maintenance strategies, choosing for the particular machines. This is important to do because it also drives which tools and sensors you use to monitor your assets. If you want to enable condition-based maintenance, is a handheld device good enough? Or is it the machine critical enough that you would need an online condition monitoring system?

CDA: How is Fluke Reliability’s software different from others on the market?

CA: Our new concept is connected reliability. Connected reliability means that we add different data sources, connecting hardware and software. And those data sources could be a handheld measurement device. It could be an alignment device. It could be an online sensor or a thermographic image camera. That data is fed into our condition monitoring software and connected into our computerised maintenance management system (CMMS). So, you can actually create work orders from condition monitoring data, then see if the machinery is repaired and get the feedback loop within in our software. It gives you a complete 360-degree view of your plant.

CDA: There are many different condition monitoring sensors on the market today. How can a maintenance team determine which sensors to use?

CA: You need to categorise your machinery. For example, if you have a standard motor pump, there is often months between the time when failure appears, and the time when it gets so bad that have to stop the machinery. So, it’s enough to have a handheld device and go our every few weeks to measure the equipment and trend this data. Now, a wind turbine is a completely different story. It is probably offshore and not accessible. So, if you have a problem, you cannot go there, or to go there is very expensive. So here you need to have online systems. What kind of sensor you select is driven by the complexity of the machine, the criticality of the machine, and the time till failure. Fluke Reliability offers expert consulting services to help customers categorise their machinery types as well.

CDA: Machine misalignment can be one of the primary causes for downtime. How can maintenance teams combat this?

CA: Machine misalignment together with machinery unbalance are the main driver of downtime. The point of condition monitoring is not only to measure and trend data to make repairs. A really good maintenance strategy starts when you install the machine. It is the first time that you check your installation. And the installation check should not only be with a laser-alignment device. The next step is to have a vibration-based check on your machinery.

This second step is also to be sure that your production quality is quite good. For example, we have a machine and cable producer in Germany who checks his vibration levels on his machinery regularly because he knows that excessive vibration actually leads to bad products. So, to combat the problem of misalignment and unbalance, you need a shaft-alignment tool as well as vibration measurement.

- IO-LInk Now Included

- As Long As The Wind Blows

- CONDITION MONITORING FOR THE COMMON MAN

- Breakdown Avoided Thanks To Condition Monitoring

- "Try & Buy" Offer For Thermal Imaging Camera

- New generation condition monitoring

- Diagnostics from a distance

- Power plant protection

- Real-time monitoring

- Cost-effective protection for smaller machinery