|

Charlotte Stonestreet

Managing Editor |

| Home> | AUTOMATION | >Condition Monitoring | >New generation condition monitoring |

ARTICLE

New generation condition monitoring

22 October 2013

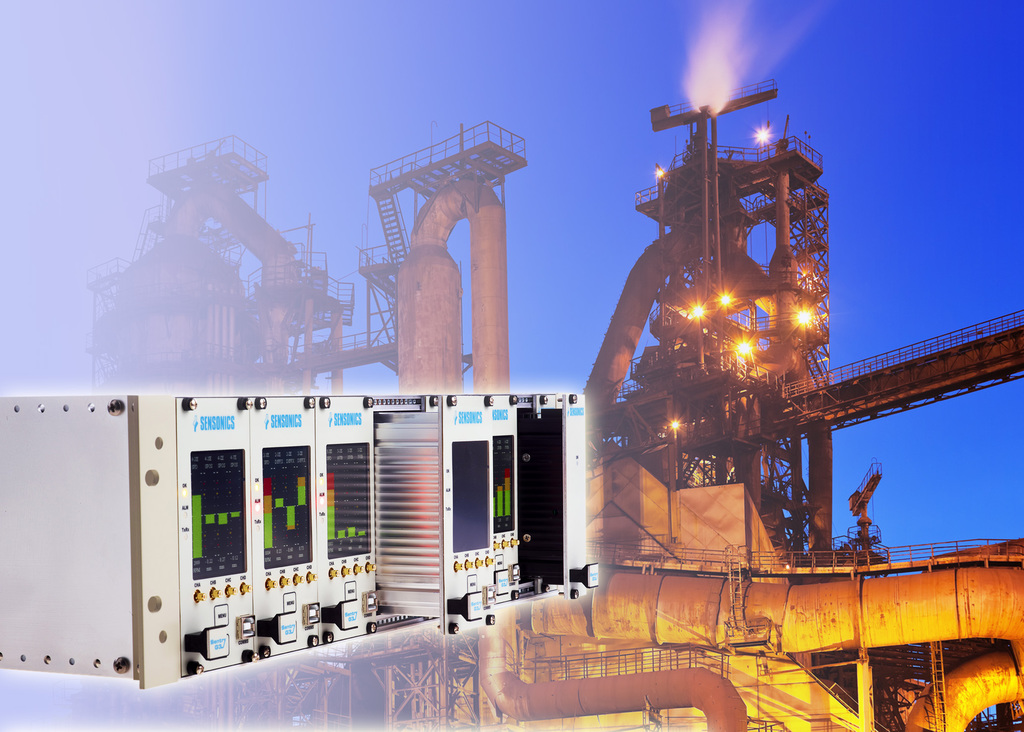

Condition monitoring specialist, Sensonics has been part of a major project involving the relighting of the blast furnace at the SSI steelworks in Redcar, on Teeside, following a major upgrade of the facility’s turbo-blowers control systems.

The new Sensonics system comprised a total of 15 sets of Senturion proximity probes monitoring a range of functions on each turbo blower, including relative shaft vibration, rotational speed and thrust positions.

The protection system comprised a 19in rack-mounted Sentry G3 system retrofitted into the existing floor standing panel, along with 16 channels of relative shaft vibration monitoring.

MORE FROM THIS COMPANY

- Cost-effective monitoring & protection for smaller plant

- Taking machinery protection to the next level

- Essential wind turbine monitoring

- Machinery protection system

- Overspeed protection

- Proximity probe system

- Sensonics expands calibration & site support services

- Power plant protection

- Vibration sensor for low speed rotating machinery

- Cost-effective protection for smaller machinery

RELATED ARTICLES

- IO-LInk Now Included

- As Long As The Wind Blows

- CONDITION MONITORING FOR THE COMMON MAN

- Breakdown Avoided Thanks To Condition Monitoring

- "Try & Buy" Offer For Thermal Imaging Camera

- Diagnostics from a distance

- Power plant protection

- Real-time monitoring

- Cost-effective protection for smaller machinery

- Bearings & condition monitoring training

OTHER ARTICLES IN THIS SECTION