|

Charlotte Stonestreet

Managing Editor |

| Home> | AUTOMATION | >Handling & Logistics | >Sustainability through supply chain management |

Sustainability through supply chain management

16 August 2023

Sustainability doesn’t have to come at a cost, in fact many companies are finding that their environmental initiatives are saving them money. Ian Manning looks at opportunities to be found in supply chain management applications

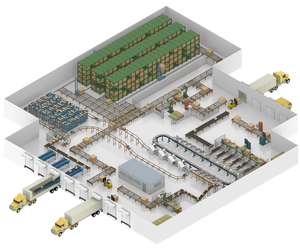

IN ONE particular distribution centre application, maintaining the control of Returnable Transport Items (RTI) was proving to be extremely challenging as different suppliers use different RTI.

Once the RTI has been emptied, it has to be stored before being returned to the supplier. The distribution centre was upgrading its inventory control by utilising Turck Banner’s RFID system, which can read hundreds of tags almost simultaneously as they pass through a gate. In addition to the products having an RFID tag, a tag was added to the RTI. As a result, the task of checking-in product inventory was greatly improved and product traceability enhanced – which were the primary objectives of the upgrade.

The simple addition of tags to the RTI facilitated the emptied RTI to be identified and directed to the allocated storage area, based upon the type of RTI and the supplier. Damaged RTI were also recorded by their tag enabling the supplier to easily identify, repair or remove them. Although RTI are designed to protect the product that they contain during transport, a damaged RTI can often be the cause of the product being damaged.

The distribution centre achieved its primary objectives of becoming more efficient and saving costs. Whilst using RTI is in the majority of cases far more sustainable than using single use packaging, the operation was able to enhance its sustainability by greatly reducing product damage and waste from damaged RTI.

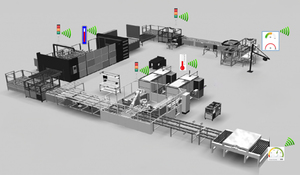

Streamlining supply to assembly stations

While supply chain management is often thought of as only involving external companies, improvements can often be made in the movement of products around your own premises.

Turck Banner was recently approached by a prestigious motor manufacturer to supply a simple light and a switch. When we asked about the application and business objectives driving the request, it became obvious that, working in partnership with each other, we could make huge improvements in the process of moving product from the main warehouse all the way to the assembly station.

As a result of implementing the changes, the takt time (time to produce a finished product) was reduced, allowing them to increase production, which in turn paid for the changes. The customer also reduced its internal transport and maintenance costs, thus improving sustainability.

UV Barcoding for invisible traceability

Even in industries where traceability is not a legal requirement, it is often becoming a business requirement, in order to generate the data required for improving processes and driving efficiency.

Barcoding is often a cheap and reliable method of marking a product for tracking and traceability. The barcode can be made in a number of ways ranging from Direct Product Marks (DPM) that are etched or stamped into the product, to adhesive labels attached to the product. The majority of these barcodes are visible to the naked eye and consume space on the product.

Ultraviolet ink is only visible when illuminated with a blacklight. By using a filter that blocks visible light but allows UV light to pass, it is possible to print a UV barcode on top of a product that already contains printing or decoration. This facilitates tracking and traceability with all the associated sustainability advantages, without spoiling the aesthetics of a product or requiring a larger product and packaging to accommodate the barcode.

These are just three examples where careful investment in the right products can have a significant impact on both short and long term savings, at the same time making the product or process more sustainable.

Ian Manning is marketing manager at Turck Banner

Key Points

- Adding RFID tags to Returnable Transport Items enables easy identification and return, enhancing efficiency and saving cost

- Optimising the movement of product around manufacturing facilities reduces internal transport and maintenance requirements

- UV barcoding facilitates tracking and traceability with associated sustainability advantages, without spoiling product aesthetics