|

Charlotte Stonestreet

Managing Editor |

ARTICLE

The benefits of centralised lubrication systems

30 October 2018

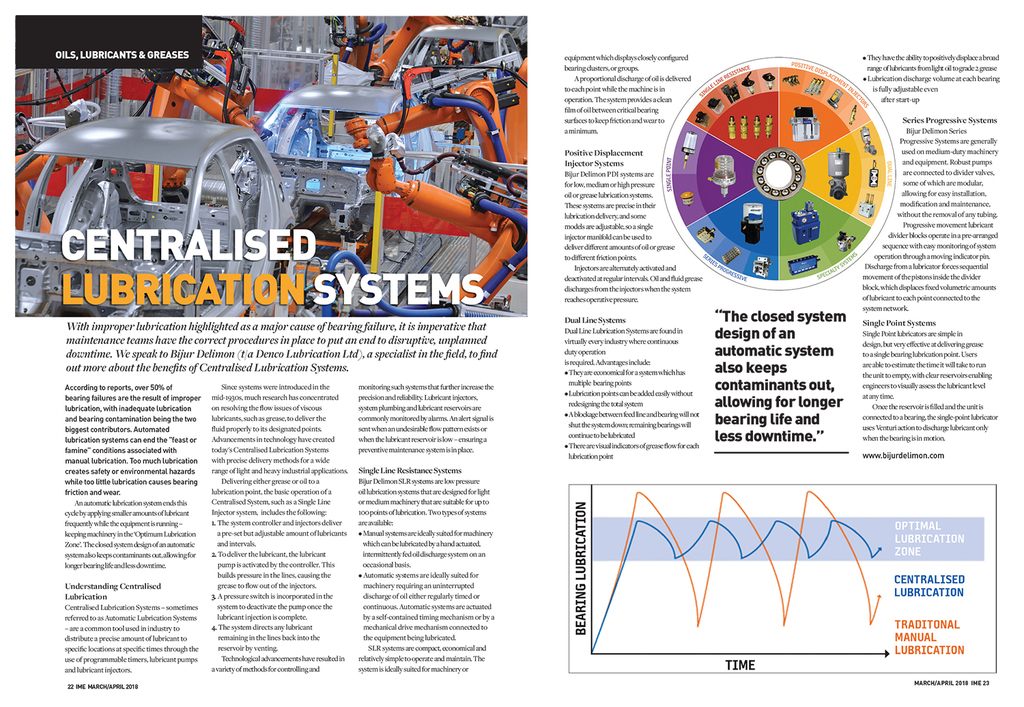

The closed system design of an automatic system also keeps contaminants out, allowing for longer bearing life and less downtime.

With improper lubrication highlighted as a major cause of bearing failure, it is imperative that maintenance teams have the correct procedures in place to put an end to disruptive, unplanned downtime. We speak to Bijur Delimon (t/a Denco Lubrication Ltd), a specialist in the field, to find out more about the benefits of Centralised Lubrication Systems.

MORE FROM THIS COMPANY

- InVMA enables delivery of Connected Healthcare Devices.

- PTC and InVMA supporting a winning project at Birmingham City University Innovation Fest

- Remote monitoring in the oil industry

- CorDEX Announces Launch Of All New TOUGHPIX DIGITHERM Digital Imaging Camera Series

- Valuekeep launches a new analytics dashboard add-on to their offer

- Ultrasound solutions for predictive maintenance

- Turnkey hovercraft drivetrain guarding

- The Health & Safety Event to introduce Machinery Safety Zone

- Condmaster Ruby 2019

- Technical experts in maintenance and reliability announced as key speakers in new-look Maintec seminar programme

RELATED ARTICLES

- UK engineering professionals to tackle top technical questions live at Maintec 2018

- Smart monitoring for maintenance and part quality

- Modern Maintenance Matters

- Predictive maintenance pushes technology boundaries

- The patchy case of maintenance in the Food & Drink industry

- Five essential health & safety updates for business leaders in 2018

- Adapting the supply chain to maintenance needs

- Bosch Rexroth confirms event partnership for Maintec 2018

- Leading trade body BSIF announces support for Maintec 2018

- PTC and InVMA supporting a winning project at Birmingham City University Innovation Fest

OTHER ARTICLES IN THIS SECTION