|

Charlotte Stonestreet

Managing Editor |

| Home> | CONTROLS | >Motion Controls | >Welding-robot guidance system |

Editor's Pick

Welding-robot guidance system

10 August 2016

E/O converters make data transmission possible by using laser diodes to convert a telephone microphone's electromagnetic pulses into optical pulses and dispatching them into the fibre optics. Their manufacture requires special precision welding devices, one of which is Nanosystec’s NanoWeld.

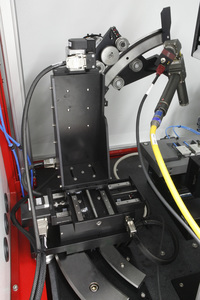

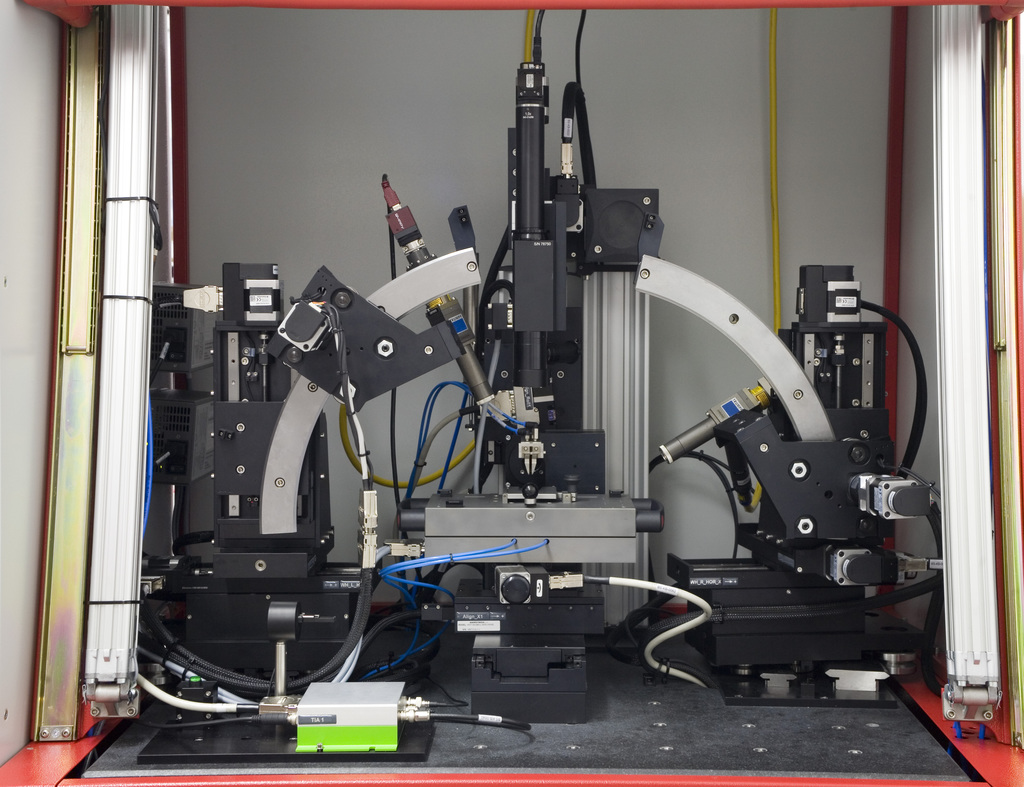

In the centre of the device is an adjustable load plate which aligns diode lasers and fibre optics accurately with each other. As the fibre optics have a diameter of just ten micrometres and the diode laser must hit a target exactly in the centre, this involves movement in the 100 nanometre (nm) range. By way of comparison: in a piece of metal 1nm is more or less equivalent to the length of a row of four atoms. Put another way: a human hair is some 700 times thicker than 100nm.

As soon as fine alignment has taken place two laser welding heads are brought into play which fix the fibre optics, encased in a metal sleeve, in place with a weld seam from two sides. Here too, precision plays a key role. "One of the challenges for the NanoWeld concept was to identify a control system in the supplier market in which lasers can be relied on to move within a range of 10%," according to Gunter Hummelt, technical director at Nanosystec. "In order to save space and build a more compact device we didn't want to work with an X-Y system but with a circular track system."

Hummelt turned to linear motion specialist HepcoMotion and its PRT2 ring guides and ring segments. This system comprises of a spectrum of rings and ring segments which are also available in high-grade steel, with a variety of diameters, which can be combined with straight guide rails to form a number of open and closed sections of track. The NanoWeld system uses four ring elements: two 90-degree segments with a width of 44 mm which project above the load plate, and two further 90-degree segments with a width of 76 mm on the base. "The rails are very strong and durable", according to Hummelt. "This gives us a competitive edge in that it reduces the cost of maintaining the system."

- HARMONIC CANCELLATION

- Integrated Motion Control

- New 4th Generation PH Series Servo Planetary Gears are Largest in Class and offer Engineers even more benefits

- Driving Trends & Developments

- EtherCAT I/O is Tightly Integrated into Aerotech's A3200 Automation Machine Controller

- Galvo and Controller Combination Offers Infinite Field of View and 24-Bit Resolution

- Control systems

- Rail Coupling Minimises Downtime

- Custom Motion System For CT Scanner

- Full Servo Motion Advantages At A Fraction Of The Cost