|

Charlotte Stonestreet

Managing Editor |

ARTICLE

IE4 MOTORS – THE FUTURE NOW WITH ADDED BENEFITS

29 November 2013

As from January 2013, the Directive 2009/125/EC for Energy related Products (ErP) came into effect with significant impact upon compressors, fans and pumps

The Directive stipulates the minimum efficiency requirements for energy consuming products. It ups the game from the previous EuP Directive 2005/32/EC and energy using products covered must comply or they cannot be offered in European markets. These energy efficiency requirements will be stepped up again in 2015.

The total compressor/fan/pump assembly is covered by ErP – direct drive, belt driven, etc. So it also impacts upon the motors employed, which must also meet appropriate EU standards. From June 2011, electric motors had to comply with IE2.

From 1 January 2015 this efficiency requirement for relevant equipment will be stepped up again when IE3 motors (or IE2 + VSD) will become mandatory for 7.5kW – 375kW. This requirement will also cover down to 0.75kW from 1 January 2017.

These changes occupy the time of design engineers throughout Europe, however, by looking forward, this step-by-step progress can be avoided by designing-in now existing motors that are already compliant with the higher level IE4 The obvious benefit of doing this is the elimination of expensive re-working of designs to accommodate a later minimum requirement. Whilst helping to achieve this goal, new Lafert permanent magnet High Performance motors also offer engineers the opportunity to potentially shrink their designs, both in size and weight. This might facilitate installation and/or transportation, benefits that are attractive to the end user.

These benefits are combined with the advantages of enhanced control. The new HPS (High Performance Standalone) IE4 compliant motors are compatible with many standard drives, consequently performance can be optimised effectively to ensure better operation capabilities.

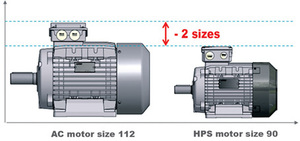

Unlike IE3 and other makes of IE4 motors which are made in equivalent standard frames, Lafert’s HPS IE4 motors are some two frames smaller than current units, thereby offering significant space and weight advantages. For example, an IEC 5.5kW motor, 112 frame motor weighs 34kg whilst a Lafert HPS IE4 5.5kW motor comes as a 90 frame unit weighing 16kg.

Currently Lafert is offering its HPS motors ex-stock in sizes from 1.1kW to 18.5kW @ 1800rpm and up to 5.5kW @ 3600rpm (full range covers 0,55kW to 30kW). This means OEM’s can order now for short notice delivery for development work.

In addition to the HPS motor, Lafert also offers a motor/drive integrated package (HPI), also IE4 compliant. Power output range is 0.37 to 30kW with a speed range up to 6000rpm.

Both these motors are based upon the combination of standard squirrel cage induction motor technology with that of the servo permanent magnet motor and the product of Lafert’s own in-house expertise in both motor types.

The total compressor/fan/pump assembly is covered by ErP – direct drive, belt driven, etc. So it also impacts upon the motors employed, which must also meet appropriate EU standards. From June 2011, electric motors had to comply with IE2.

From 1 January 2015 this efficiency requirement for relevant equipment will be stepped up again when IE3 motors (or IE2 + VSD) will become mandatory for 7.5kW – 375kW. This requirement will also cover down to 0.75kW from 1 January 2017.

These changes occupy the time of design engineers throughout Europe, however, by looking forward, this step-by-step progress can be avoided by designing-in now existing motors that are already compliant with the higher level IE4 The obvious benefit of doing this is the elimination of expensive re-working of designs to accommodate a later minimum requirement. Whilst helping to achieve this goal, new Lafert permanent magnet High Performance motors also offer engineers the opportunity to potentially shrink their designs, both in size and weight. This might facilitate installation and/or transportation, benefits that are attractive to the end user.

These benefits are combined with the advantages of enhanced control. The new HPS (High Performance Standalone) IE4 compliant motors are compatible with many standard drives, consequently performance can be optimised effectively to ensure better operation capabilities.

Unlike IE3 and other makes of IE4 motors which are made in equivalent standard frames, Lafert’s HPS IE4 motors are some two frames smaller than current units, thereby offering significant space and weight advantages. For example, an IEC 5.5kW motor, 112 frame motor weighs 34kg whilst a Lafert HPS IE4 5.5kW motor comes as a 90 frame unit weighing 16kg.

Currently Lafert is offering its HPS motors ex-stock in sizes from 1.1kW to 18.5kW @ 1800rpm and up to 5.5kW @ 3600rpm (full range covers 0,55kW to 30kW). This means OEM’s can order now for short notice delivery for development work.

In addition to the HPS motor, Lafert also offers a motor/drive integrated package (HPI), also IE4 compliant. Power output range is 0.37 to 30kW with a speed range up to 6000rpm.

Both these motors are based upon the combination of standard squirrel cage induction motor technology with that of the servo permanent magnet motor and the product of Lafert’s own in-house expertise in both motor types.

MORE FROM THIS COMPANY

RELATED ARTICLES

- Robotics & Automation 2013

- Automation on the upswing

- Amendment to Commission Regulation (EC) No 640/2009

- Confidence returning to UK manufacturing technologies

- A national success story

- Automation: plan to succeed

- EPTDA expands in the Middle East & Africa

- Innovating for the recovery, innovating for the future

- A system-oriented approach to assessing energy efficiency

- tGARD IN ACTION

OTHER ARTICLES IN THIS SECTION