|

Charlotte Stonestreet

Managing Editor |

ARTICLE

SYSMAC AUTOMATION PLATFORM

02 December 2013

Sysmac is the latest machine automation platform from Omron with integration throughout: from controller to software

The guiding principles behind the Sysmac automation platform are:

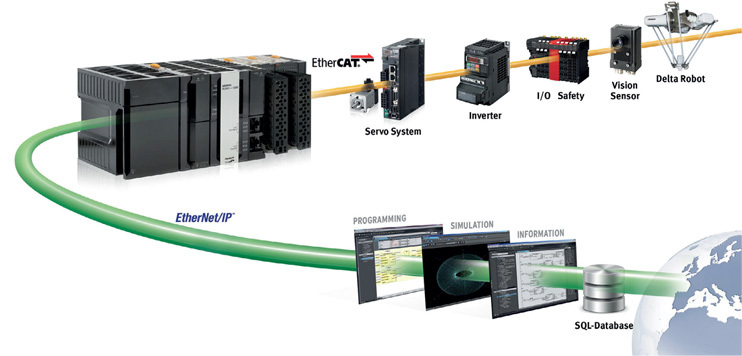

The result: a powerful and robust automation platform that integrates motion, logic sequencing, robotics, networking and vision inspection, and a new software that includes configuration, programming, simulation and monitoring using a fast machine network (EtherCAT) to control motion, vision, sensors and actuators.

SYSMAC CONTROLLER

The NJ-series Machine Automation Controller is at the heart of the platform that offers speed, flexibility and scalability of software-centric architecture without compromising on the traditional reliability and robustness that you have come to expect from Omron PLCs.

REMOTE I/O

With either modular or block-type distributed I/O, you can choose the style best suited to your needs. The NX-series modular EtherCAT I/O system supports synchronous (Distributed Clock) high-speed I/O. The modular SmartSlice series can be connected to various open networks, and offers preventive maintenance features and hot-swapping. The block-type GX series are dedicated for EtherCAT and have a fixed I/O size.

SERVOS

Great machines are born from a perfect match between control and mechanics. G5 gives you that extra edge to build more accurate, faster, smaller and safer machines.

SOFTWARE

Created to give you complete control over your automation system, Sysmac Studio integrates configuration, programming, monitoring and simulation in a simple interface. Driving the powerful NJ-series machine automation controller gives you total control of the entire machine via a single and easy to use software.

INVERTERS

Thanks to its advanced design and algorithms, the MX2 provides smooth control down to zero speed, plus precise operation for cyclic operations and torque control capability in open loop. The MX2 is fully integrated within the Sysmac automation platform.

VISION SENSORS

The FQ-M series is a vision sensor designed specifically for pick and place applications. It comes with EtherCAT embedded and can be configured and monitored from Sysmac Studio software. The FQ-M series is compact, fast and includes an incremental encoder input for easy tracking and calibration.

ROBOTS

The Delta solution can achieve up to 200 cycles per minute and can be synchronised with multiple conveyors to perform on-the-fly pick & place operations. The system offers two types of robot arms: Delta and Mini Delta. The NJ controller offers a response time of 2ms when controlling eight Delta robots or 1ms when controlling four robots.

INTEGRATED SAFETY CONTROL

The Sysmac automation platform integrates the safety solution within one connection and one software concept. One connection is realised through the use of Safety over EtherCAT - FSoE - protocol. Sysmac Studio software is utilised for configuration, programming and maintenance.

The NX safety system consists of safety controller and safety I/O units and can be freely distributed in an I/O rack throughout the network, mixing them in any combination with standard NX I/O.

ONE MACHINE NETWORK

EtherCAT is the fastest emerging network for machine automation. It’s fast, accurate and highly efficient. One connection via the NJSeries controller allows seamless control and communication with both the machine and the factory. The NJ-Series controllers join the world standard factory automation network, EtherNet/IP, with the best Ethernet-based machine control network, EtherCAT.

- One control for the entire machine or production cell

- Open communication and open programming standards

The result: a powerful and robust automation platform that integrates motion, logic sequencing, robotics, networking and vision inspection, and a new software that includes configuration, programming, simulation and monitoring using a fast machine network (EtherCAT) to control motion, vision, sensors and actuators.

SYSMAC CONTROLLER

The NJ-series Machine Automation Controller is at the heart of the platform that offers speed, flexibility and scalability of software-centric architecture without compromising on the traditional reliability and robustness that you have come to expect from Omron PLCs.

REMOTE I/O

With either modular or block-type distributed I/O, you can choose the style best suited to your needs. The NX-series modular EtherCAT I/O system supports synchronous (Distributed Clock) high-speed I/O. The modular SmartSlice series can be connected to various open networks, and offers preventive maintenance features and hot-swapping. The block-type GX series are dedicated for EtherCAT and have a fixed I/O size.

SERVOS

Great machines are born from a perfect match between control and mechanics. G5 gives you that extra edge to build more accurate, faster, smaller and safer machines.

SOFTWARE

Created to give you complete control over your automation system, Sysmac Studio integrates configuration, programming, monitoring and simulation in a simple interface. Driving the powerful NJ-series machine automation controller gives you total control of the entire machine via a single and easy to use software.

INVERTERS

Thanks to its advanced design and algorithms, the MX2 provides smooth control down to zero speed, plus precise operation for cyclic operations and torque control capability in open loop. The MX2 is fully integrated within the Sysmac automation platform.

VISION SENSORS

The FQ-M series is a vision sensor designed specifically for pick and place applications. It comes with EtherCAT embedded and can be configured and monitored from Sysmac Studio software. The FQ-M series is compact, fast and includes an incremental encoder input for easy tracking and calibration.

ROBOTS

The Delta solution can achieve up to 200 cycles per minute and can be synchronised with multiple conveyors to perform on-the-fly pick & place operations. The system offers two types of robot arms: Delta and Mini Delta. The NJ controller offers a response time of 2ms when controlling eight Delta robots or 1ms when controlling four robots.

INTEGRATED SAFETY CONTROL

The Sysmac automation platform integrates the safety solution within one connection and one software concept. One connection is realised through the use of Safety over EtherCAT - FSoE - protocol. Sysmac Studio software is utilised for configuration, programming and maintenance.

The NX safety system consists of safety controller and safety I/O units and can be freely distributed in an I/O rack throughout the network, mixing them in any combination with standard NX I/O.

ONE MACHINE NETWORK

EtherCAT is the fastest emerging network for machine automation. It’s fast, accurate and highly efficient. One connection via the NJSeries controller allows seamless control and communication with both the machine and the factory. The NJ-Series controllers join the world standard factory automation network, EtherNet/IP, with the best Ethernet-based machine control network, EtherCAT.

MORE FROM THIS COMPANY

- Behind the curtain of automated inspection

- Paving the way with digital enablement

- OMRON adds EtherCAT models to i4L SCARA robot series

- Trends in AI & robotics beyond 2020

- Integrated automation for your machines

- Cobot palletising solution

- Sensing where safety is paramount

- Condition monitoring devices

- From optimisation to autonomy

- Ultra-compact code reader

RELATED ARTICLES

- Robotics & Automation 2013

- Automation on the upswing

- Amendment to Commission Regulation (EC) No 640/2009

- Confidence returning to UK manufacturing technologies

- A national success story

- Automation: plan to succeed

- EPTDA expands in the Middle East & Africa

- Innovating for the recovery, innovating for the future

- A system-oriented approach to assessing energy efficiency

- tGARD IN ACTION

OTHER ARTICLES IN THIS SECTION