|

Charlotte Stonestreet

Managing Editor |

Pushed to the limit

09 November 2016

mayr power transmission has produced a technical paper entitled 'Pushed to the limit' covering reliable high-speed torque limiters for performance test stands.

Motor test stands and roller dynamometers in the automotive sector place maximum demands on drive systems. Therefore, it is necessary to protect the frequently expensive test pieces and the sensitive measurement units reliably from overload damages.

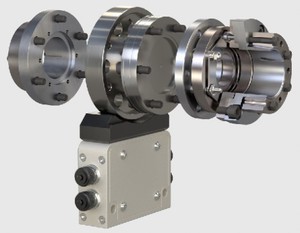

With its EAS-HSC and EAS-HSE high-speed clutches, mayr power transmission has developed clutches specially tailored to the requirements of test stand technology. They convince users through high quality and provide reliable protection without influencing the measurement signals.

In modern automotive and motor bike production, intensive research and development as well as the compliance with the highest demands on quality are indispensable prerequisites today. As a result, component and functional test stands, such as motor test stands and roller dynamometers, which permit the practical simulation of the complete spectrum of loads on a drive line and its components, are becoming increasingly significant. In particular during the development stage, the systems are frequently pushed to the limit. Under these extreme load conditions, malfunction of the test pieces is possible.

In order to protect both the frequently expensive test piece and the sensitive measurement units against overload damage, torque limiting clutches are used in many test stand applications. These torque limiters must comply with the extreme demands of test stand technology, and also work reliably at very high speeds. With the backlash-free and torsionally-rigid EAS-HSC and EAS-HSE torque limiters, mayr® power transmission therefore provides overload protection, which is especially tailored to the requirements in high-speed applications. The clutches convince users through their high quality and provide maximum safety without influencing the measurement signal.

High balance quality for optimum running smoothness

Should the torque in a test stand exceed the set limit values of the torque limiter, then the clutch disengages and disconnects the input and output within fractions of a second. Following an overload, the measuring shaft may at worst have to be re-calibrated; but the torque limiter will reliably prevent expensive damage to the drive line or the test piece.

The high-speed torque limiters EAS-HSC and EAS-HSE transmit the torque backlash-free and with high torsional rigidity. They are compact, have a high performance density and a low mass moment of inertia. An EAS-HSE clutch with a torque of 1000 Nm, for example, weighs significantly less than 10 kg. With an extremely small outer diameter of 125 mm, a relatively large bore diameter of up to 60 mm is permitted for mounting the shaft. Another important prerequisite for the use of a torque limiter in high-speed applications is the high balance quality of each individual component in order to achieve optimum running smoothness in the drive line. As the speed increases, imbalance causes significant centrifugal forces and vibrations.

This places the entire test stand design under strain, leads to irregular running and falsifies the test results of the measurement equipment. Therefore, optimisation of the mass imbalance was the top priority during the development of the EAS-HSC and EAS-HSE clutches. Design measures ensure than the many individual components incorporated in the torque limiters do not change their position within the clutch, not even following overload. Furthermore, the clutches are balanced in a completely assembled state to a balance quality of G 2.5, at a reference speed of 3000rpm.

High-quality clutch bearing

The joint clearance between the respective customer shaft and the clutch bore is minimised so that a completely assembled torque limiter, balanced and set to the required speed, ensures the necessary balance quality, even following integration into the respective test stand application. The clutch bores are designed with quality 6 as a standard, and the frictionally locking shaft hub connection ensures backlash-free torque transmission.

In addition, a high-quality clutch bearing absorbs the external reaction forces which act on the output flange of the high-speed clutches. As a result, these forces have no influence on the trigger mechanism, and a precise torque limitation is maintained. Furthermore, the clutch bearing is designed so that it can absorb extremely high accelerations. These occur, for example, when the drive line is blocked as the torque limiting clutch suddenly disengages, and the input side of the clutch is strongly accelerated against the output side.

Compact and powerful

In normal operation, the EAS-HSC transmits the torque via balls which simultaneously engage into recesses of the hub and the output flange. Cup springs pre-tension the ball bearings via a ring. The high spring force is proportional to the transmittable torque. This principle remains backlash-free even when the recesses are worn. mayr® power transmission uses cup springs in torque limiting clutches with a falling characteristic curve. Therefore the torque is transmitted in a torsionally rigid manner up to the pre-set trigger value. In case of overload, the pre-tension force of the spring reduces, and the clutch triggers extremely accurately.

After disengagement, a special overload mechanism ensures that the clutch remains in the disengaged position. The drive line can slow down freely, and as a result absolutely no ratchetting impacts occur during the overtravel time which might negatively influence the drive line, especially the torque measurement equipment in the test stand. The design of the torque transmission unit is such that re-engagement is only possible at the disengagement position. In operation, the individual parts of the clutch therefore always have the same angular position to one another, and the balance quality is maintained. The special overload mechanism enables simple, quick re-engagement without major exertion of force.

High-speed – up to 20,000rpm

On the EAS-HSE, individual overload elements transmit the torque via positive locking. In case of overload, these overload elements disengage and separate the input and output almost without residual torque and with a high degree of switch-off and repetitive accuracy. The kinetic energy of the rotating masses stored in the system can slow down freely. The elements do not automatically re-engage, but remain separated until they are re-engaged manually or by means of a device. The position for the synchronised re-engagement for maintenance of the balance quality is clearly marked on the clutch.

In the standard design, the compact EAS-HSC clutches cover a torque range up to 1000 Nm, the EAS-HSE based on individual overload elements have a torque range of up to 10,000 Nm. Both clutches achieve speeds up to 12,000 rpm. In special designs, higher torques and higher speeds of up to 20,000 rpm are permitted.

For precise measurement results

Besides torque limiting clutches, shaft misalignment compensation couplings are a decisively important accessory part in test stands, as they minimise the disturbance variables acting on the measurement flange. These disturbance variables, or so-called parasitic loads, often occur due to alignment errors in the drive line.

Misalignments between the input and output side occur in almost all applications. For this purpose, shaft misalignment compensation couplings are used together with the measurement flange. Based on the tried and tested backlash-free and torsionally rigid ROBA®-DS series, mayr® power transmission offers a design of its compensation coupling specially aligned to measurement flanges, which provides the ideal prerequisites for precise measurement results. These couplings transmit the torque backlash-free and with extreme torsional rigidity manner, and compensate for radial, axial and angular shaft misalignments. They therefore not only provide precise measurement results, but also protect the bearings installed in the shaft train against unwanted loads, and consequently from unnecessary downtimes and costs. In addition to high running smoothness and a low mass moment of inertia, the couplings are distinguished by high balance quality, and are particularly robust and resistant.

For a combination of shaft coupling and torque limiting clutches, mayr® power transmission provides complete solutions from a single source. For this purpose, our tradition-steeped family business can call on comprehensive expertise and many years of experience in development and design. All our products are extensively tested on calibrated test stands and accurately adjusted to the required values of the respective application.

- Intelligent brake control

- Overload protection

- Electromagnetic backlash-free linear brake

- Torque measuring coupling

- Accurate measuring results

- High performance in a compact design

- Brake monitoring without sensors

- Roba-linearstop Gets Dynamic Brake Approval

- Torque limiters for packaging industry

- Backlash-free servo couplings