|

Charlotte Stonestreet

Managing Editor |

| Home> | AUTOMATION | >Handling & Logistics | >Easily programmed robotic palletising |

Editor's Pick

Easily programmed robotic palletising

04 May 2017

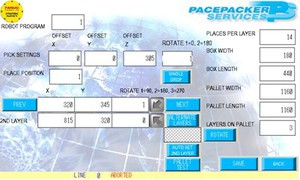

Representing a significant technology advance in automated packaging, Pacepacker Services’s new Pallet+ programming technology is reported to bring about new levels of flexibility and agility, coupled with significant time, energy and cost savings, as well as offering the possibility that engineer-programming visits could soon be a thing of the past for in-house packers.

Rather than relying solely on robot teach pendants, Pallet+ allows users to easily programme, change, store and recall new or revised robotic palletising ‘recipes’ using a more intuitive and easy-to-use interface. Catering to ever-changing product formats and designs, including volume, shape and size, Pallet+ users can easily modify the packaging parameters on the fly and in a very short space of time, with little or no robot programming knowledge. More importantly, once set up, modifying recipes doesn’t require constant intervention from the machine’s supplier.

“Traditional reprogramming of palletising machines can be a laborious, time consuming, trial-and-error process in primary, secondary and even tertiary packaging processes,” highlights Lee Moss, Pacepacker’s electrical design engineer, who created the Pallet+ software.

- Cost effective pick & place

- Diagnostics from a distance

- Cost effective Cartesian

- Versatile robot packing solutions

- Resist the impulse to blame the robots

- New-generation robotic palletiser

- Pacepacker extends portfolio with Festo Mechatronics

- Pick & place robots

- LOCAL MP LAUNCHES ROBOTIC PACKING INNOVATIONS

- The food factory cobots are coming … or are they?