|

Charlotte Stonestreet

Managing Editor |

| Home> | AUTOMATION | >Robots | >Augmented humans |

Editor's Pick

Augmented humans

21 November 2017

Hollywood has created a huge buzz around robotic exoskeleton suits. Films such as Iron Man show humans with superhuman abilities because of robotic add-ons. Chris Johnson, managing director of SMB Bearings, explains the importance of choosing specialised bearings as the development into this technology advances in real life.

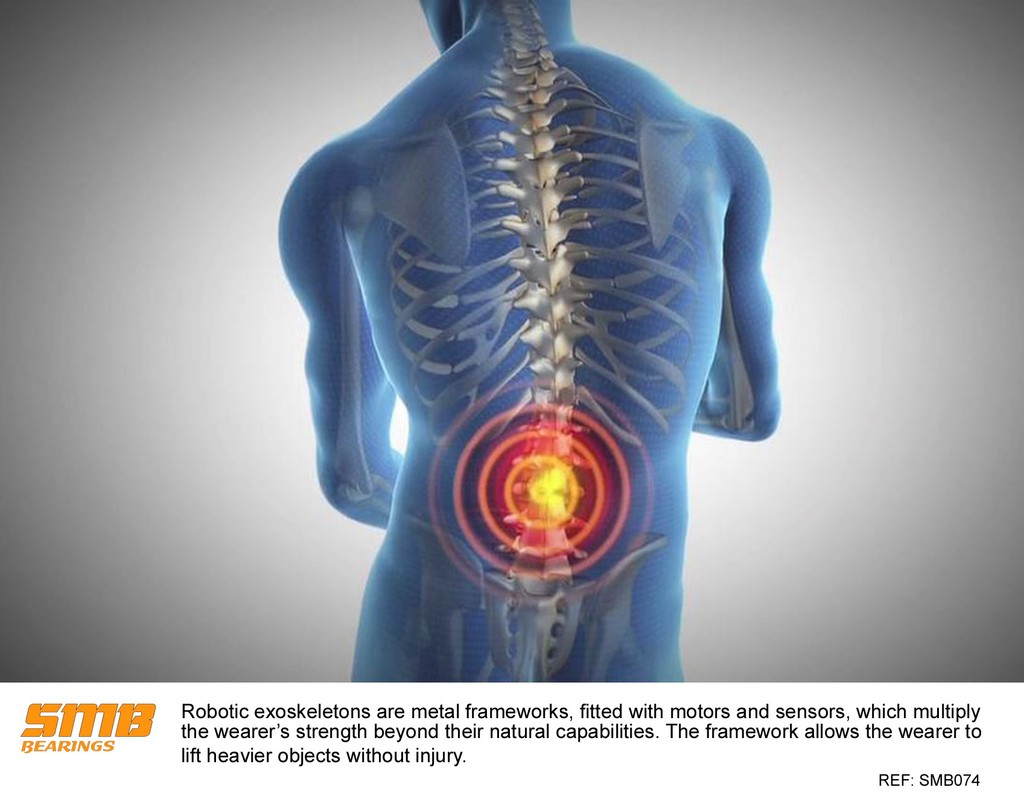

Robotic exoskeletons are metal frameworks, fitted with motors and sensors, which multiply the wearer’s strength beyond their natural capabilities. The framework allows the wearer to lift heavier objects without injury, offering huge potential benefits for the health of workers in factories, warehouses and even nursing homes.

The point of these exoskeletons is to augment the human workforce, enhancing a person's own ability. As Homayoon Kazerooni, a University of California robotics professor, explained earlier this year, “It’s not about making workers superman. We want to eliminate the pain of the physical labour of these guys.” Kazerooni certainly brings this Hollywood technology back down to earth, breaking the Hollywood fantasy expectation.

Robotic exoskeletons could one day create a society where anyone, regardless of strength, can partake in industrial work processes. Panasonic laid the foundations for this with its AWN-03 assist robot. Using auto-assist technology, this robotic exoskeleton uses sensors to detect when the wearer is lifting heavy objects. In response, it raises the wearer's upper body and pushes on the user's thighs to reduce strain on the back by 15kg.

Development

Just as the health and strength of real human skeletons are dependent on good decisions, such as diet, to ensure effective movement and longevity, robotic skeletons are also dependant on similar wisdom. With specialists in robot software, sensor technology and mechanical engineers working together to drive the development of robotic exoskeletons, every decision is a make or break contribution — including bearing choice.

Sapporo Precision, the leading bearing specialist, is already supplying EZO thin-type precision bearings for robotic exoskeleton applications. Apart from taking up less space and being much lighter than standard types, these bearings have the high precision and good rotational accuracy required for robotic exoskeletons, as a result of EZO’s advanced manufacturing techniques and quality control.

Additionally, if robotic exoskeletons are to be used in a controlled environment such as a clean room, specialist bearing lubricants will also be required. This reduces risk of contamination caused by greases giving off vapour, a problem known as outgassing. Bearing materials and the lubricants must be carefully chosen to avoid such complications.

Powered exoskeleton suits are fast becoming a reality across various industries, and are no longer just a Hollywood concept. With an estimated several hundred commercial and experimental exoskeletons now in operation globally, this technology is not just for Iron Man, but for a regular man or woman. Even if current exoskeleton suits don’t bestow superhuman powers, they will increasingly impact workers' lives by assisting people in performing heavy labour jobs with fewer injuries.

- Revolutionise testing with bearings

- SMB Bearings supports F1 in Schools national champions

- Are counterfeit bearings on the rise?

- Grasping the next generation of robotics

- Ceramic bearings for medical robots

- Bearing the harsh environment

- How is bearing technology changing?

- Robotics boom creates components shortage

- Robotics bearings white paper

- Ceramic vs hybrid bearings

- Balls to Gravity

- ROBOTS GIVE FASTER CELL TOOL CHANGE TIMES

- ROBOT FOR DELICATE ASSEMBLY

- NUMBER OF ROBOTS IN UK ON THE RISE

- The future is bright - The future is automation!

- High Demand For Grant

- More Capacity, Less Space

- FREEBIRD - THE THIRD DIMENSION

- PRECISION ROBOT CELL FOR THE PHARMACEUTICAL INDUSTRY

- ROBOT SALES REACH ALL TIME HIGH