|

Charlotte Stonestreet

Managing Editor |

| Home> | POWER TRANSMISSION | >Bearings | >Corrosion resistant, non-magnetic plastic bearings |

Corrosion resistant, non-magnetic plastic bearings

14 August 2017

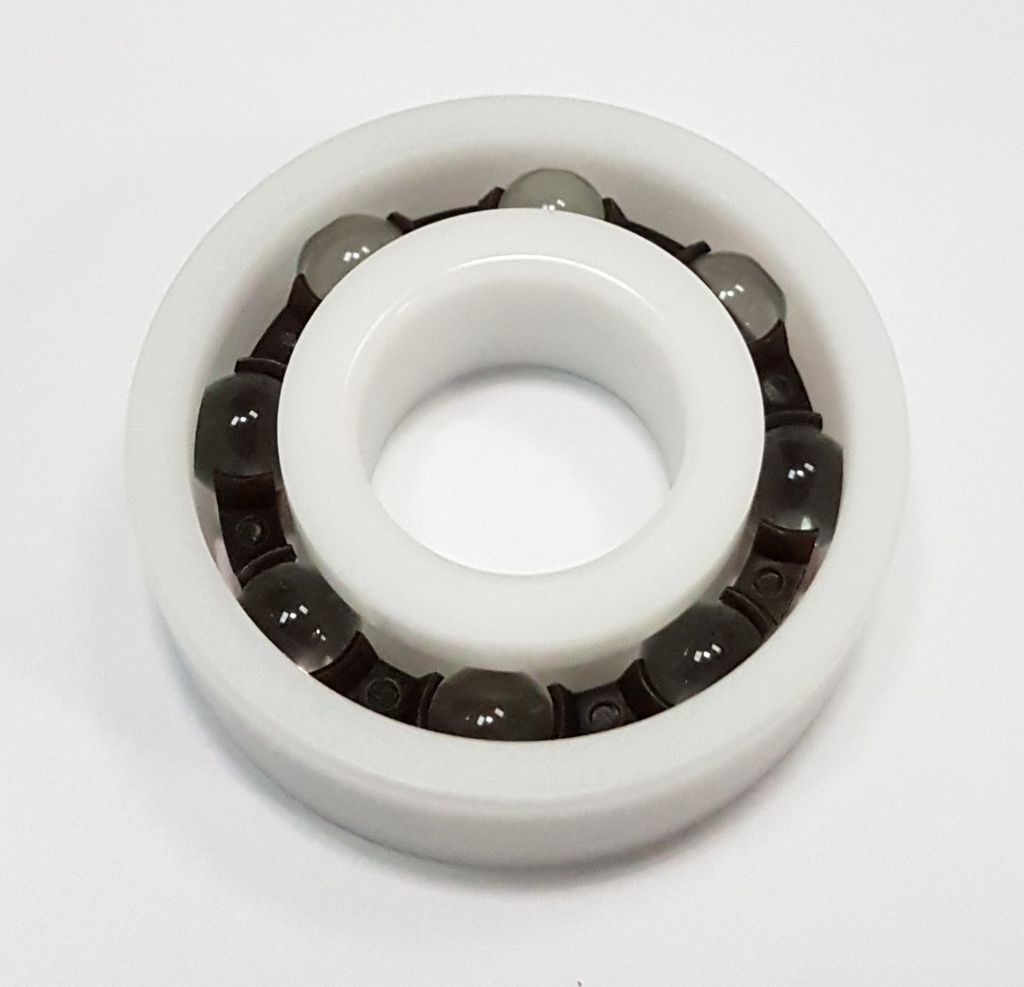

Miniature and specialist bearings provider, SMB Bearings, has launched a range of corrosion resistant, non-magnetic plastic bearings.

Bearings used across the chemical, pharmaceutical and food industry need to be able to handle corrosive fluids and materials. Those used in food applications need to cope with regular wash-downs and must also meet strict hygiene standards. Plastic bearings are non-corrosive and are usually unlubricated which makes them ideal. The standard range are acetal resin with glass or 316 stainless steel balls but they can be offered in a variety of materials from PEEK to PVDF to cope with a wide range of corrosive fluids.

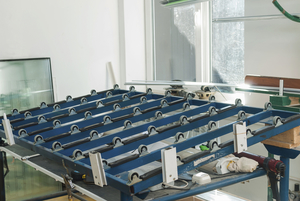

As the material is relatively soft, plastic bearings should only be used in low load applications. They are normally used in lower precision applications, such as conveyor rollers and trolleys.

- How is bearing technology changing?

- Go greener with chrome steel bearings

- Augmented humans

- Grease or oil?

- Bearing the harsh environment

- SMB Bearings supports F1 in Schools national champions

- Avoiding electrical damage with conductive lubrication

- Full ceramic bearings

- Custom or off-the-shelf?

- Robotics bearings white paper