|

Charlotte Stonestreet

Managing Editor |

Maintenance free

05 March 2018

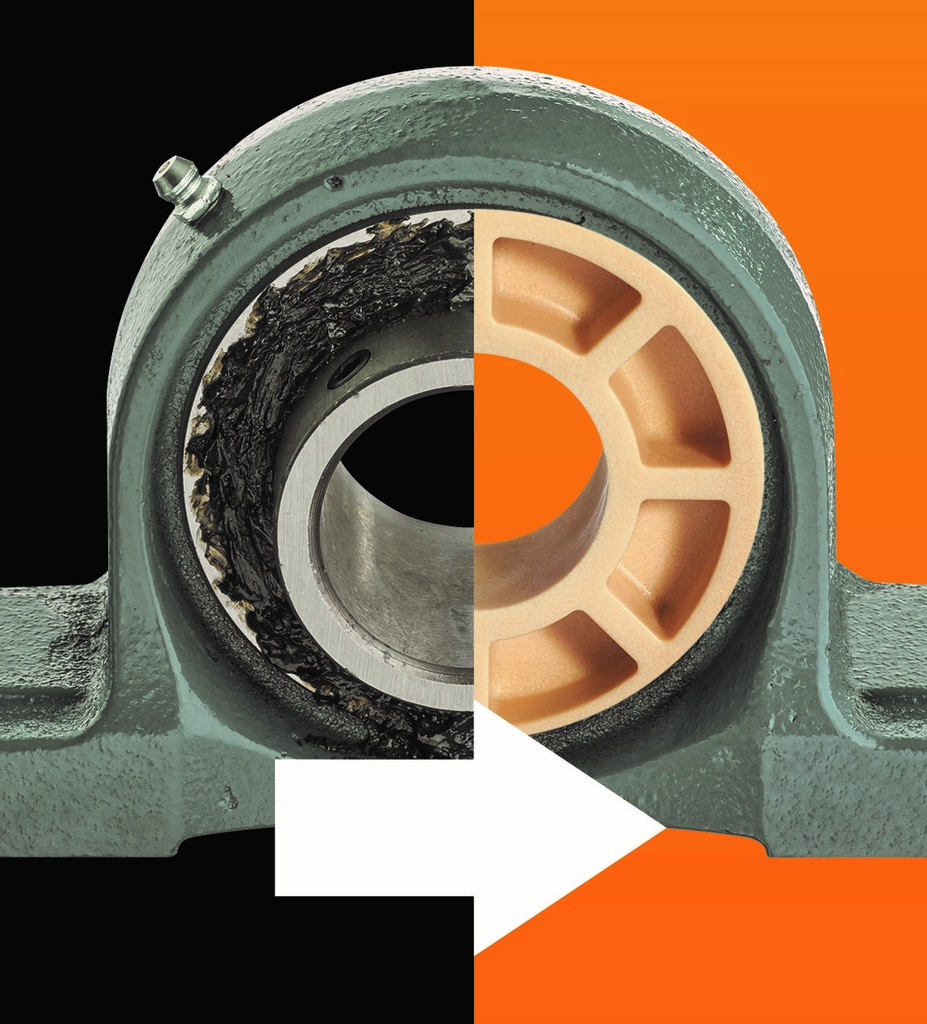

New from igus are igubal spherical balls that can be inserted into existing metallic pillow block and flange bearing housings within a few seconds. These bearings, which are often used in construction machines and conveyor systems, are exposed to harsh environments requiring regular lubrication and maintenance.

The igubal spherical balls are injection moulded in the high-performance plastic iglidur J, which is self-lubricating. The retrofitted bearings therefore are maintenance-free. Another advantage is that due to the absence of lubricant, dirt and impurities can no longer adhere to the bearings , reducing maintenance downtime.

The long service life of the igubal spherical balls has already been proven in a biomass chipper. The original metal bearings on the conveyor belt of the machine had to be lubricated each month. When the flange bearings were retrofitted with igubal spherical balls, the bearings remained wear-free for more than a year, without the need for lubrication and maintenance.

- Low cost roller energy chain and guiding trough

- Ready-to-install 7th axis

- Online design of double gears for 3D printing

- igus goes into the blue

- igus introduces new speedifit service

- Coming to a green space near you soon

- Linear robots for cost-effective automation

- Quick RoI robotics awards seek entrants

- Smart plastics increase plant availability

- Smart bearings help prevent machine failure

- No related articles listed