|

Charlotte Stonestreet

Managing Editor |

| Home> | MACHINE BUILDING & ENGINEERING | >Cables | >Drag chain selection |

Drag chain selection

14 June 2018

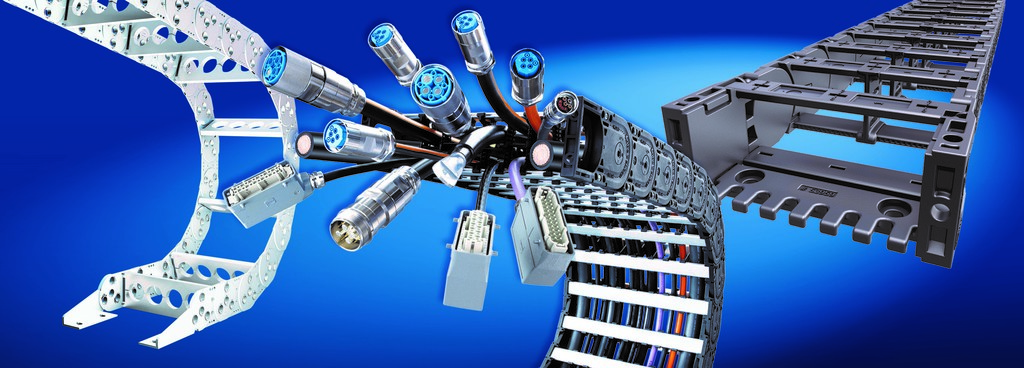

The full drag chain range of KabelSchlepp Metool includes steel cable carriers as well as plastic and hybrid systems. They are successfully used in machine tools, crane systems or complex applications like offshore oil rigs or space travel.

The specification of a drag chain system is determined by technical parameters, such as dimensional requirements, accessibility of the compartments, the unsupported travel to cover or the additional loads to be managed. But there are many more determinants to consider in the choice of materials. The effect of certain operation conditions, options available, whether higher investment is balanced by reduced down times is a vast field for users.

Standard plastic drag chains have proven successful in a temperature range from -30 °C to over 100 °C. Some special applications, however, present specifications which can only be met by special plastics. This includes

- customised explosion protection solutions

- heat protection components

- closed cable carriers preventing red-hot chips from entering or damaging the cable carriers

- clean room requirements

However, plastic cable carriers are not suitable for any application. Steel chains are best for:

- extremely rough environmental conditions

- very high temperatures or

- high mechanical loads

- aggressive atmosphere

They can ensure very extensive unsupported lengths with high additional loads through cables. Compared to plastic chains they can be built with a significantly more compact design and the temperature and atmosphere aspect is significantly easier to handle.

Hybrid chains are a powerful material combination that combine the benefits of both steel and plastic chains. The side bands consist of steel or plastic while the cables are guided by an aluminium stay system.

- This material combination offers many advantages:

- easy access to the inserted cables

- increased width variability by mm increments

- large cable chain widths without installation of additional side bands

- reduced cable wear and increased service life of the cables

Whether steel, hybrid or plastic: materials are determined by the customer's application. Different materials in the product portfolio mean that KABELSCHLEPP Metool is prepared for any sophisticated application and offers impartial advice. Today there is an ideal solution for any individual challenge – whether in standard widths or adapted to customer requirements in millimetre increments.

The complete range of products and accessories comprises over 100,000 variants in total from stock and consists of matching accessories starting from cables, clamps, guide channel systems up to complete systems ready to install.