|

Charlotte Stonestreet

Managing Editor |

| Home> | MACHINE BUILDING & ENGINEERING | >Machinery Safety | >Flexible relay solution simplifies safety implementation |

| Home> | MACHINE BUILDING & ENGINEERING | >Relays | >Flexible relay solution simplifies safety implementation |

Editor's Pick

Flexible relay solution simplifies safety implementation

28 April 2014

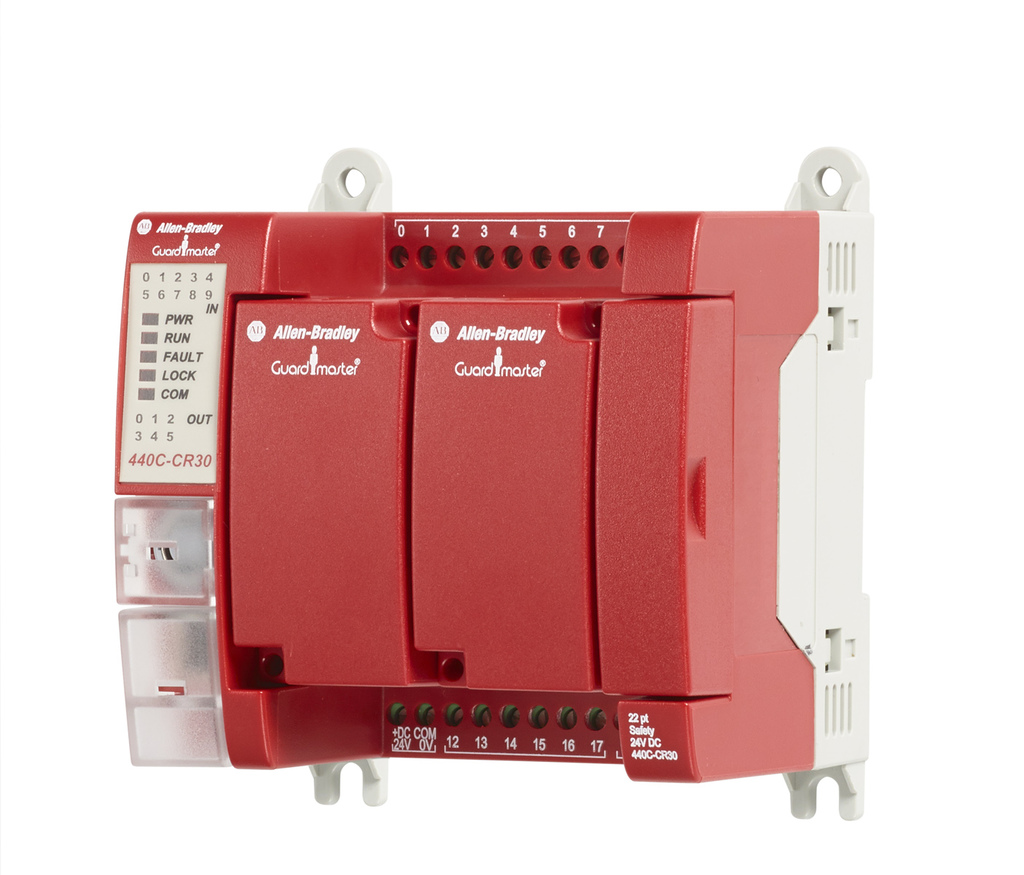

Machine builders can now easily implement required safety functions while improving productivity with the Allen-Bradley Guardmaster 440CCR30 safety relay from Rockwell Automation.

Users can program the safety relay through the free Connected Components Workbench software from Rockwell Automation. Connected Components Workbench software reduces programming time and helps increase productivity by allowing users to create, control and monitor a safety system in the same software environment as their standard control. The Guardmaster 440C-CR30 safety relay meets PLe, SIL 3 per EN ISO 13849-1 and IEC 62061. It is ideal for applications requiring four to nine safety circuits and control of up to five zones.

"Machine builders across all industries are seeking safety solutions that go beyond meeting compliance requirements to helping significantly increase both configuration and operation productivity,” said Thomas Helpenstein, product manager, Rockwell Automation. "The flexible, compact Guardmaster 440CCR30 safety relay configured via Connected Components Workbench software meets their needs for improved safety, uptime and productivity.”

The distinct graphical user interface and drag-and-drop capabilities of the software help guide users through a simple process of selecting certified safety function blocks for the safety relay. Once programmed, an embedded Modbus interface allows the safety relay to easily communicate diagnostic data to AllenBradley Micro800 controllers, Allen-Bradley PanelView graphic terminals or AllenBradley CompactLogix controllers. Leveraging the embedded communication capabilities and the software allows users to easily monitor, troubleshoot and quickly modify their applications, including performing partial or conditioned shutdowns, as needed. Five status and 16 user-configurable LEDs on the safety relay’s faceplate provide local diagnostics to further aid in status reporting and troubleshooting.

With 22 on-board safety I/O points, including six configurable I/O, the Guardmaster 440CCR30 safety relay is the ideal solution for applications requiring multiple safety zones. Without growing the footprint, the safety relay also can be expanded with two standard Micro800 plug-in modules to support 16 additional standard I/O points, saving valuable safety I/O points for user safety systems. The safety relay also permits interoperation with multiple standard-control platforms, enabling the safety control to remain the same even if the standard control changes.

- Visualisation platform is out of this world!

- Modular transport system

- Rockwell Automation and Michelin strengthen collaboration

- Unlocking data potential

- Faster & more secure data access

- Rockwell and Taurob partner to provide end-to-end solutions

- Factories care about outcomes, not AI

- Easing entry to smart manufacturing

- Linear motion control system

- Motion Application Efficiency Improved Without Sacrificing Performance