|

Charlotte Stonestreet

Managing Editor |

| Home> | CONTROLS | >Monitoring | >Motion monitoring |

| Home> | CONTROLS | >Motion Controls | >Motion monitoring |

Editor's Pick

Motion monitoring

06 October 2014

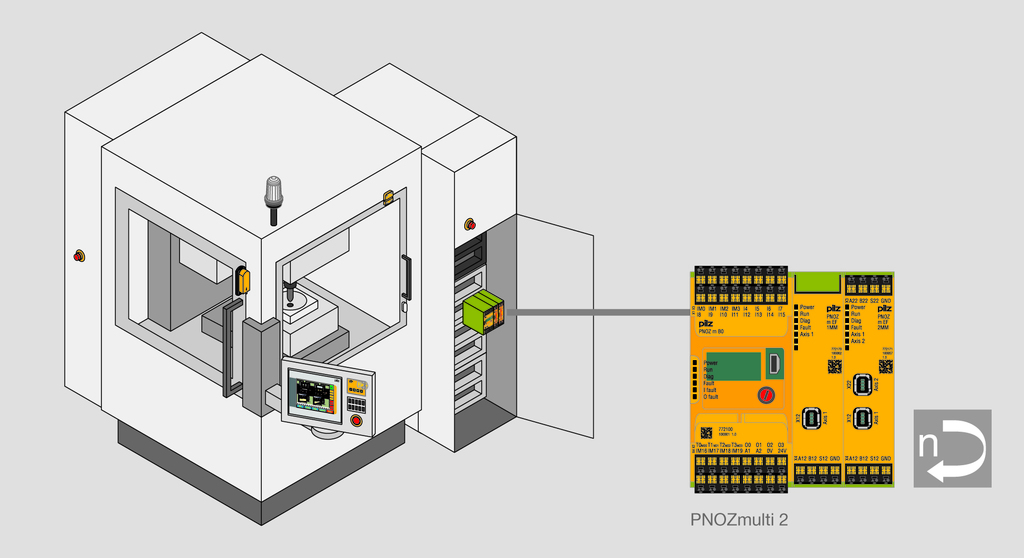

Pilz is expanding its PNOZmulti 2 range of configurable control systems with new safe motion monitoring modules, which provide safe monitoring of one or two axes in drives, enabling safety functions to be created and monitored with ease. The modules can be used in any industry, but are a particular advantage in machine tool manufacturing.

All safety functions are easy to implement in accordance with EN 61800-5-2 for adjustable speed electrical power drive systems. As such it is possible to achieve optimum availability of plant and machinery, coupled with a high level of safety.

All common incremental encoders can also be connected using drive-specific connection cables via the industry-compatible interface Mini I/O.

- Safeguarding frequent access danger zones

- Machinery safety training

- Slimline safety switches

- Configurable control systems

- Force & pressure measurement system

- Fault-finding skills are invaluable – master the ability with Pilz UK

- Expert Advice

- Safety and security go hand in hand

- Control system with application simulation

- All-in-one safety gate

- HARMONIC CANCELLATION

- Motion Control

- Looks Good On Paper

- Integrated Motion Control

- Intelligent Biogas Analysers Control Desulphurisation

- New 4th Generation PH Series Servo Planetary Gears are Largest in Class and offer Engineers even more benefits

- Displays & Controls PH & ORP Values

- Custom Capacitive Interface Panels

- Driving Trends & Developments

- EtherCAT I/O is Tightly Integrated into Aerotech's A3200 Automation Machine Controller