|

Charlotte Stonestreet

Managing Editor |

| Home> | DRIVES & MOTORS | >Linear Actuators | >Tubular linear motors to replace pneumatic actuators |

Tubular linear motors to replace pneumatic actuators

14 July 2015

The emphasis of Dunkermotoren’s stand at PPMA 2015 will be the All Electric / Servo Machine and the company will be presenting its range of motors to support this trend, including the full range of Tubular Linear Motors for replacing pneumatic actuators – providing higher throughput, less maintenance, longer life and lower running costs than alternatives.

Also being exhibited will be a variety of motors suitable for use in automatic format adjustment, these allow fast and easy changeovers reducing downtime and providing extra flexibility during production that can ultimately lead to reduced inventory and operating costs.

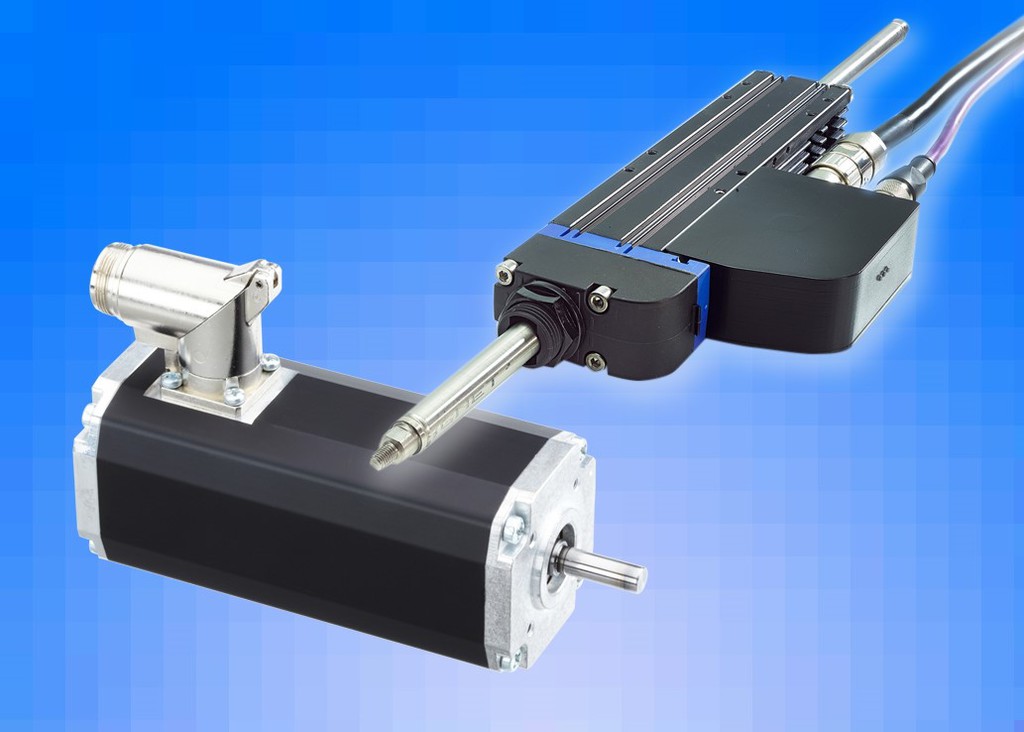

Of particular interest will be the company's tubular linear motor, the ST11 actuator which is ideal for stand-alone applications such as rejecters and diverters. The unit features an integrated controller option that provides machine builders and designers with the benefits of easy integration, significantly reduced and simplified wiring. It features a range of analogue and digital inputs and outputs, with CAN, Profibus and EtherCAT communications protocols available as standard. Once programmed only power is required to operate in stand-alone mode, with programming completed using Dunkermotoren’s own proven and established Drive Assistant.

The controller mounts easily with all models in the ST11 series and maintains a combined IP67 rating with the motor although can also be positioned away from the motor in the same way as a conventional controller. This ensures optimum flexibility along with the advantages of a single-source of supply for all your motion and control needs.

Although suited for use in a wide range of motion control applications, being faster than stepper motors with ballscrews and more precise than belt-drive systems, the ST11 with Integrated Controller is particularly ideal for replacing pneumatics in all-electric machines due to its efficient, low-maintenance and environmentally sound features.

Saving space, reducing overall design and assembly time whilst improving performance are familiar objectives for designers, so the new BG45SI brushless DC motors from Dunkermotoren also on display, will be of interest. The length of the BG45x15SI has been reduced from 120 to 88mm and the length of the more powerful BG45x30SI reduced from 135 to 103mm, a reduction of 25% whilst maintaining the same power, torque capabilities and motor efficiencies.

These compact and integral sub-100W power units offer high power density combined with true 4-quadrant digital speed control. The motor connector design has also been modified to ensure further space saving and convenience in mounting and connection.

With a 12 or 24 volt power source, at a nominal speed of 3000rpm, the longer of the two units, the BC45x30SI is continuous duty rated for 80W power output. Based on the improved design, however, the motors can achieve peak powers of four times the continuous duty rating and therefore, a starting torque of up to 100Ncm is possible. Stand E14

- Compact & efficient

- Integrated controller

- Integrated amplifier & controller

- Hygienic linear motors

- Optimal solutions for linear movement

- Technology for tomorrow's automation... today

- Powerful, compact brushless rotary DC motor

- Tubular linear motors

- Precise, fast positioning

- Integrated controller option

- LOW COST ACTUATORS

- CONSTANT LUBRICATION

- Solar Linear Actuator

- Precision, Dynamics & Durability

- SCHAEFFLER DEVELOPS WORLD RECORD BREAKING TANDEM LINEAR ACTUATOR

- Continuous Motion System

- Tritex II™ AC Powered Actuators

- Exlar GS Series Linear Actuator Family

- FT Series - Linear Actuators

- Integrated amplifier & controller