|

Charlotte Stonestreet

Managing Editor |

| Home> | POWER TRANSMISSION | >Gearboxes | >Improved control for dynamic motors |

Editor's Pick

Improved control for dynamic motors

10 August 2017

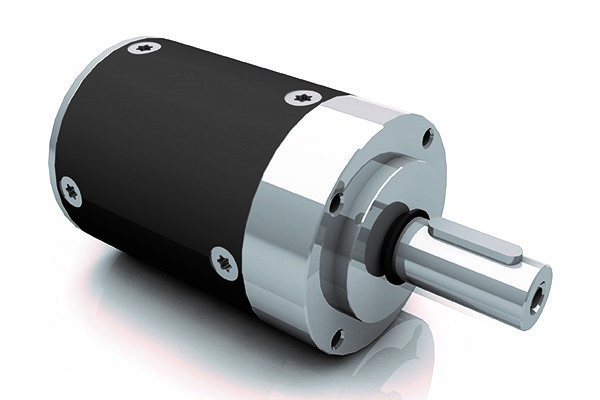

Developed to provide high nominal torque of up to 160Nm and acceleration torque of up to 320Nm, Dunkermotoren has expanded its range of gearboxes with the PLG 63 HP, PLG 75 HP and PLG 95 HP. Even under occasional load peaks of up to 480Nm tunits remain undamaged and continue to operate normally.

Saving space is often a key objective for machine builders and these new gearbox options ensure a very compact drive and gearbox solution. The planetary gearboxes are designed so that they do not require any coupling or flange to be mounted to the motor which results in the drive length being reduced to an absolute minimum.

When tooth motor shafts are utilised, one stage gearboxes can be achieved with a reduction ratio of 14, 5:1.

- Technology for tomorrow's automation... today

- Precise, fast positioning

- Powerful, compact brushless rotary DC motor

- Tubular linear motors to replace pneumatic actuators

- BG motors with field-oriented control

- Tubular linear motors

- Integrated control & electronics

- Integrated amplifier & controller

- Incorporates power supply & all functions

- Ultra-compact brushless DC motor

- GEARBOX IS CHEAPER TO REPLACE THAN REPAIR

- PLANETARY/SPUR GEARBOXES

- PLANETARY GEARS WELL SUITED FOR RETROFIT

- AGEING WORM GEARS REPLACED BY PLANETARY GEARS IN SEWAGE PLANT

- REHFUSS BRINGS QUALITY AND VERSATILITY TO GEARBOX DESIGN AND SELECTION

- FLEXIBLE COUPLINGS

- GETTING THE BEST OUT OF GEARBOXES

- A Guide to the Selection

- Greater Corrosion Resistance

- Fits existing parameters