|

Charlotte Stonestreet

Managing Editor |

Bespoke disentangling

20 November 2015

The new range of MAFU Automation disentangling and feeding equipment from R. A. Rodriguez gives UK manufacturers easy access to this quality brand of specialist products. The MAFU systems are extensively used throughout Europe, allowing users to sort, feed and accurately place non-sensitive parts regardless of their size, material or geometry.

The main differentiators of MAFU technology are the reliability of the disentangling process its machines allow and the huge choice of feeding, separating and transfer elements available to enable the optimal combination to be specified. This flexibility is complemented by a wide range of productivity boosting options and quality assurance technology.

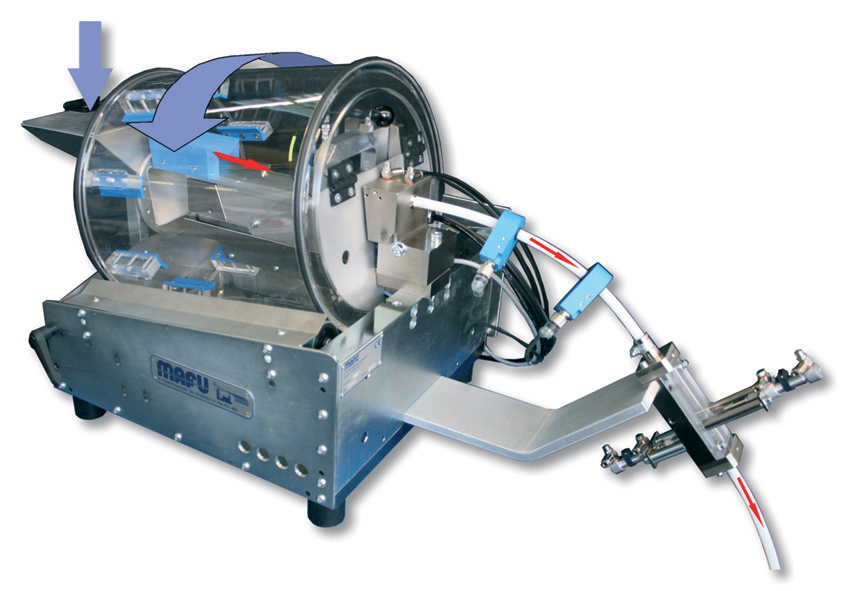

At the heart of the MAFU disentangling is its drum system. Bulk goods such as springs, pins and bent-wire parts are fed into the drum via a funnel and its rotation allows parts to be gently disentangled and released to the outlet. A variety of hopper systems are available for bulk feeding and also a wide choice of different drum designs and sizes to suit the application. These include antistatic, sieve and acrylic options.

After disentangling, the individual parts are released onto a choice of patented separation systems according to the nature of the product and how it is to be further processed. Examples are output via tube for springs, pins and sleeves; on-rail threading for circlips or rings and on-rail hanging for screws, rivets and nails.

A significant advantage of the MAFU technology is ability for one disentangling system to work with multiple tracks; up to 40 tracks have been installed for a European customer. Additionally the tracks can be equipped with a variety of sensors and image processing systems for process and quality control.

- No related articles listed