|

Charlotte Stonestreet

Managing Editor |

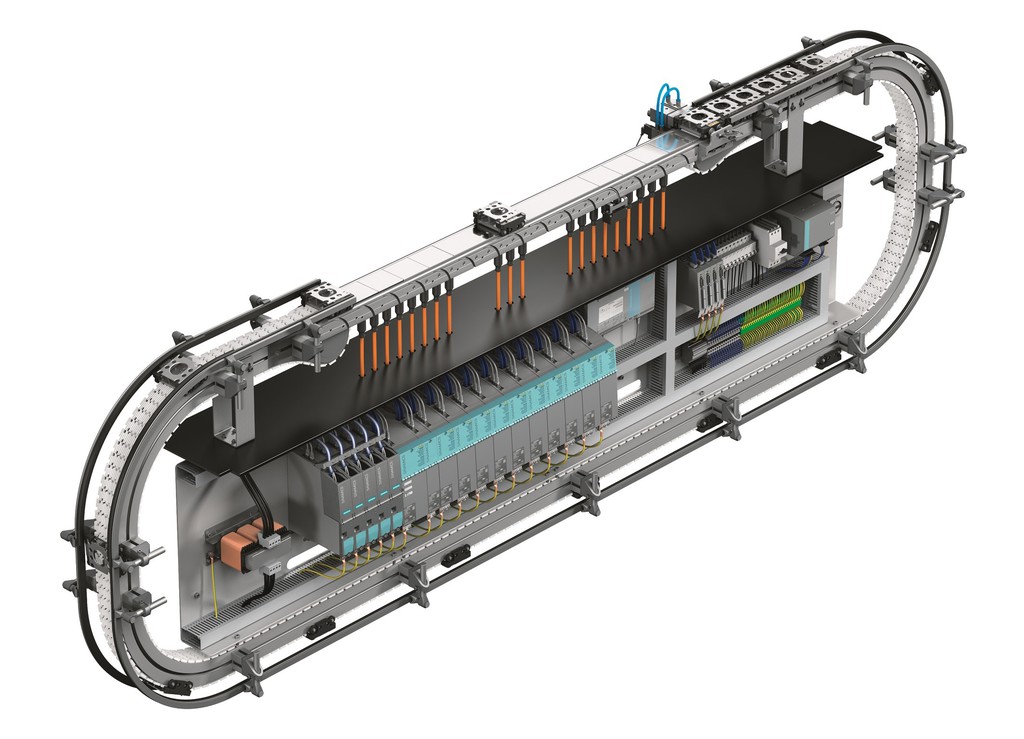

Linear motor track system

11 July 2016

At this year’s PPMA Total Show Festo will showcase exciting new developments and solutions for the processing and packaging industry.

For the first time in the UK, in collaboration with Siemens, Festo will demonstrate the Multi-Carrier-System, a new linear motor track system which delivers a flexible and modular transport solution for industrial automation. The collaboration brings together the extensive controls expertise of Siemens with Festo’s linear motor and mechanical guidance technology. Festo will also highlight some of its latest new products and demonstrate solutions for Industry 4.0.

The Multi-Carrier-System addresses the acute need for flexibility in modern manufacturing and production environments driven by increasingly complex product diversity and high levels of mass customisation. Its freely definable and configurable linear transport rail can be easily integrated into existing intralogistics systems, with precise synchronisation and seamless infeed and outfeed of transport carriers.

The movement of carriers within the system can be rapidly and easily adapted to deal with different formats, sizes and types of product – down to batch sizes of one. Applications could include cosmetics packaging with its huge number of product variants, food and beverage processing with quick seasonal changes or industrial manufacturing of customised one-off products ordered via online configurators.

Incorporating decentralised sensors and intelligence within its workpiece carriers and drives, the Multi-Carrier-System is strongly positioned to address Industry 4.0 requirements and applications. Its exceptionally flexible electromechanical design enables adaptable, reconfigurable and economic production, even for mixed requirements and small batch sizes. Its OPC-UA interface enables open integration into Industry 4.0 environments.

Visitors to the stand will also see examples of how Festo is implementing this key industrial M2M communication protocol for interoperability into its other field level controllers, alongside open interfacing to other industrial control and communications standards, including PROFINET and IO-Link. Hall 5, stand B70

- Cartesian handling benefits

- Entering the next stage with artificial intelligence

- A toast to sustainability

- PPS becomes Festo Official Partner

- Electric motion sizing tool

- Realising the potential of transformative technology

- Compact and precise electric parallel gripper

- Tips for I4.0 implementation

- Cantilever electro-mechanical drive

- Advanced dynamics