|

Charlotte Stonestreet

Managing Editor |

| Home> | POWER TRANSMISSION | >Gearboxes | >High speed, high precision |

High speed, high precision

25 June 2024

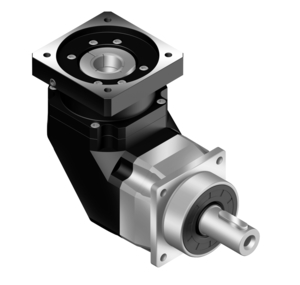

Rotary Precision Instruments (RPI) UK chooses AF Series precision planetary gearboxes from Apex Dynamics

WHEN RPI UK, the world’s largest manufacturer of rotary devices, was looking for a reliable gearbox supplier that could meet very specific requirements of high accuracy measuring and angular positioning – all with fast delivery – the company turned to Apex Dynamics, which provides market-leading delivery times of two to three weeks. In this case, the gearbox needed to fit into the existing design of a rotary table for coordinate-measuring machines (CMM), which are used for measuring components. CMMs cut down inspection times and costs for aerospace manufacturers, with no accumulation of errors. The AF Series gearbox is used in RPI UK’s LabStandard and QuadDualPurpose assemblies. It is mounted to a motor by a pulley arrangement with a belt that drives a worm and wheel arrangement.

RPI UK’s versatile QuadDualPurpose and LabStandard precision rotary axis were specifically developed to enhance the productivity and efficiency of CMMs. With the option to mount parts horizontally and vertically for inspection, the devices are ISO 10360 Part 3 compliant, deliver angular accuracy of 2 arc seconds (0.00056°) and can handle load capacities up to 1000kg.

Quieter alternative

The Apex Dynamics AF Series high precision, high speed planetary gearbox fitted into the existing space envelope on the machine without modification to the gearbox and with minimal changes to the design, providing RPI UK with a better value, quieter alternative gearbox.

Providing the highest precision, highest torque and quiet operation, each Apex AF series gearbox has 100% optimised helical gearing, low backlash and easy mounting. High precision taper roller bearings equip the gearboxes to handle high axial and radial loads and output torque ranges from 14 Nm – 2000 Nm. The compact Apex Dynamics AF Series gearboxes are constructed with precision helical planetary gears hardened to 840 HV and feature Apex’s patented input bearing system to ensure perfect concentricity.

Following rigorous R&D development, lab tests, angular calibration and in-situ testing of the Apex Dynamics gearbox, RPI has purchased and fitted 12 AF Series gearboxes to date. The company plans to continue buying gearboxes from Apex Dynamics UK because the whole implementation process ran so smoothly. The Apex Dynamics UK team worked closely with the design team at RPI UK to identify the right product and supply the required specifications, files and models.

Low backlash

RPI UK technical manager, Adrian Blake, says: “With more than 80 years’ experience in rotary measurement, high levels of accuracy are key to the success of our application-specific products. As a key component of our CMM rotary table, the low backlash provided by the AF Series gearbox means that it positions correctly, an essential feature for our machines as it forms part of the drive assembly.

“Our suppliers are incredibly important to us and we have found Apex Dynamics UK very easy to work with. In this case, demand was key to us looking for a new supplier. However, we have found the relationship with Apex Dynamics to be positive in many different ways – from providing us with a better value product to strong customer service and reduced noise, as well as the excellent lead times for delivery.

“All the gearboxes we have purchased are running smoothly and have met our calibration standards. We are now using the AF Series gearbox in two of our products and, with the QuadDualPurpose rotary table becoming increasingly popular with our customers, we look forward to strengthening our relationship with Apex Dynamics UK still further.”

- Seamless and transparent integration

- Designed for enhanced axial and radial loads

- Planetary gearbox series expanded

- Five-minute challenge

- Gearboxes for AGV applications

- Precision planetary gearboxes

- ATEX-certified precision planetary gearboxes

- Easy-to-configure motors and geared motors

- Apex Dynamics unveils first couplings range

- Gearing up for precision performance

- GEARBOX IS CHEAPER TO REPLACE THAN REPAIR

- PLANETARY/SPUR GEARBOXES

- PLANETARY GEARS WELL SUITED FOR RETROFIT

- AGEING WORM GEARS REPLACED BY PLANETARY GEARS IN SEWAGE PLANT

- REHFUSS BRINGS QUALITY AND VERSATILITY TO GEARBOX DESIGN AND SELECTION

- FLEXIBLE COUPLINGS

- GETTING THE BEST OUT OF GEARBOXES

- A Guide to the Selection

- Greater Corrosion Resistance

- Fits existing parameters