|

Charlotte Stonestreet

Managing Editor |

Actuator upgrade

05 July 2013

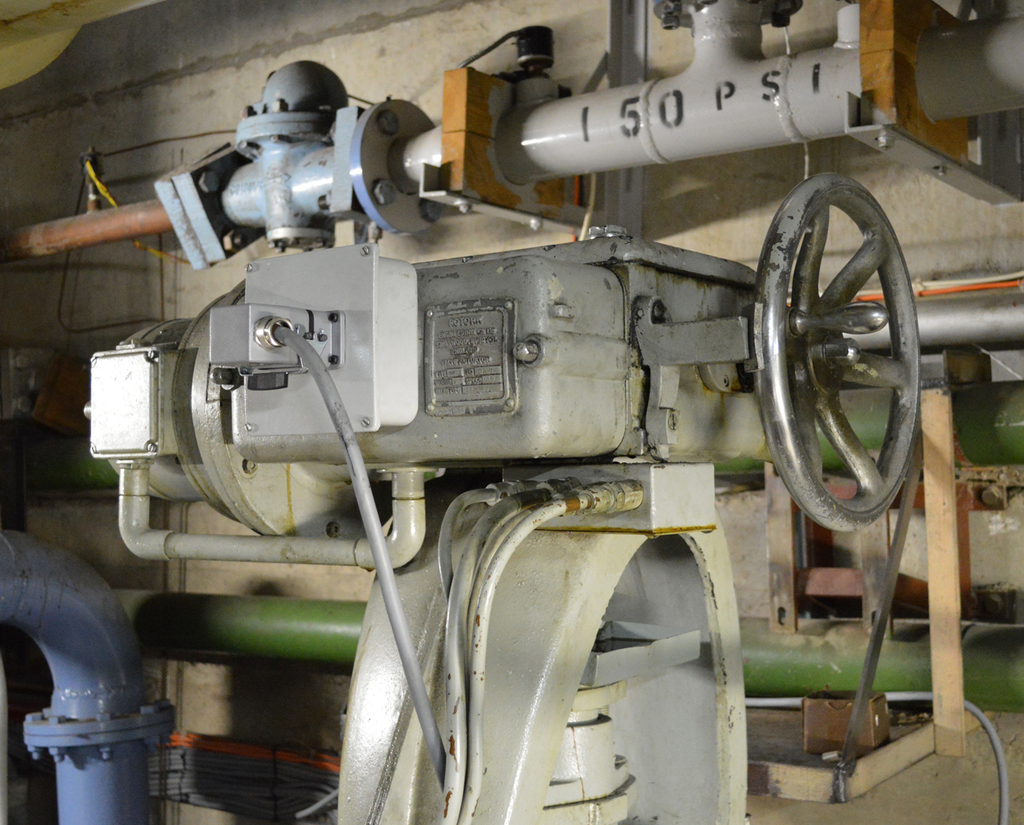

Some of the very first valve actuators to carry the Rotork name are being replaced with the company’s latest intelligent IQ3 actuators after sixty years of unbroken service on a supersonic wind tunnel.

Although designed for isolating valves, original the Rotork 100A actuators have been performing modulating duties, altering the position of large gate valves by small degrees to control the wind speeds and provide data needed for test results. The automation of this process has necessitated the replacement of these units with new IQ3M actuators, specifically designed for modulating duties.

Careful and detailed planning ensured the retrofit could be completed in the brief periods of time available between test programmes. The first two actuators were removed and the replacement IQ3M actuators installed and commissioned in two days, half the allocated time allowed before the wind tunnel was due to re-start operations.

- Actuators in water treatment plant upgrade

- Optimised stem acceptance

- MAINTENANCE FREE FOR 10 YEARS

- Service centre supports Scotland

- Intelligent actuators decrease downtime

- Passes the glass making test

- Electric & pneumatic actuation

- New reliability services programme from Rotork

- Enhanced digital smart positioner

- Rotork assists BAE Systems in upgrades