|

Charlotte Stonestreet

Managing Editor |

| Home> | AUTOMATION | >Robots | >Barrel loads of automated handling |

Barrel loads of automated handling

20 August 2013

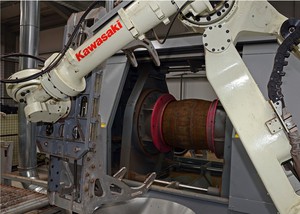

Two Kawasaki robots and a purpose designed lathe are being used in the refurbishment process of traditionally built oak barrels at Speyside Cooperage in Alloa.

Meeting a growing trend to refurbish both ends, or heads, of a barrel, Speyside Cooperage went to Aberlour Engineering with a brief to design a system to automatically handle the process of removing up to 3mm from each barrel’s internal diameter and handle it through a charring process.

Aberlour Engineering designed a horizontal lathe with powered tail stocks and two 300Kg payload Kawasaki ZX300S Robots to load and unload the barrels. The load robot picks a barrel from an infeed position and loads it into the horizontal lathe.

After the charring process the barrel is removed by the Kawasaki robot and placed onto an output conveyor.

- Multi-million cycle robot replaced after almost 20 years

- Bale handling robot

- Two arm cobot

- High speed palletising robot

- Production comes back to UK

- Robots for moulding & post-moulding processes

- Multi-million cycle robot replaced after almost 20 years

- Safety Zones Easily Programmed

- Glass experts see clear advantages with Kawasaki robots

- Paving the way for productivity

- Balls to Gravity

- ROBOTS GIVE FASTER CELL TOOL CHANGE TIMES

- ROBOT FOR DELICATE ASSEMBLY

- NUMBER OF ROBOTS IN UK ON THE RISE

- The future is bright - The future is automation!

- High Demand For Grant

- More Capacity, Less Space

- FREEBIRD - THE THIRD DIMENSION

- PRECISION ROBOT CELL FOR THE PHARMACEUTICAL INDUSTRY

- ROBOT SALES REACH ALL TIME HIGH