|

Charlotte Stonestreet

Managing Editor |

ARTICLE

DRIVE INNOVATION THAT REDUCES COSTS

29 November 2013

Geoff Spear, Marketing Manager at Lenze Ltd, describes new products and concepts that can reduce the cost of building machines.

5 STEPS TO DESIGN FREEDOM

Constant product innovation in drives & automation means that Lenze can offer you more performance for less cost. To take advantage of this new technology there are 5 steps:

- Let's meet at the idea stage, whether a simple upgrade or a totally new machine. The right decisions here save project time.

- Together we draft the concept for your motion and control requirements, keeping it simple and future oriented.

- Next we detail the solution using powerful sizing software to optimise cost, performance and energy usage.

- At your build stage we supply a package of controllers, software, drives, motors and gears, all from the Lenze portfolio.

- Finally we ensure productivity by working with you on field support from the Lenze Group worldwide.

FAST SOFTWARE

Writing software is an important task taking significant time and costs. New Lenze ‘FAST’ application software introduces standard preconfigured modules that can be applied easily.

Then cover up to 80% of machine requirement and in this area they can cut programming time by three-quarters. Fifteen modules cover motion, positioning, registration, synchronising, cam profiling, temperature control and multi-conveyor co-ordination.

SAFETY IN THE DRIVE

Putting safety functionality into the drive can give you simpler control systems, faster response and reduced machine build costs. Drive-based safety functions range from STO Safe Torque Off to the more demanding SS1, SS2, SLS and much more. We meet ENI3849-1 PL e and IEC 62061 SIL 3 with our products that are listed in the SISTEMA library. Complete control panels can be supplied.

THE NEW LENZE SMART MOTOR

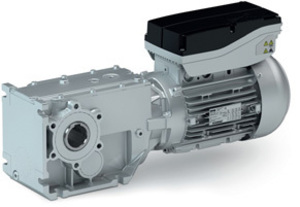

The Lenze Smart Motor is an innovation that adds intelligence to the standard AC Motor with benefits in performance, size and energy efficiency. Aimed at fixed speed applications such as conveyors, it allows the speed to be preset or adjusted anywhere from 500 to 2600r/min. Several different geared motors can be replaced by one, reducing stock costs.

Motor speed and individual start and stop ramps are set by smartphone app using the NFC Near Field Communication protocol. Integrated electronics makes a remarkable 400% starting torque available, 67% more than a motor started direct on line. This often results in selections that are one frame size smaller saving space and cost.

The Lenze Smart Motor is normally supplied as a geared motor and ranges of in-line and right-angle gearboxes are available for torques up to 600Nm. Gearbox efficiency is 96% or more. The Smart Motor also saves energy with efficiency at IE3 levels and "eco” software for partial loads.

MORE FROM THIS COMPANY

RELATED ARTICLES

- Robotics & Automation 2013

- Automation on the upswing

- Amendment to Commission Regulation (EC) No 640/2009

- Confidence returning to UK manufacturing technologies

- A national success story

- Automation: plan to succeed

- EPTDA expands in the Middle East & Africa

- Innovating for the recovery, innovating for the future

- A system-oriented approach to assessing energy efficiency

- tGARD IN ACTION

OTHER ARTICLES IN THIS SECTION