|

Charlotte Stonestreet

Managing Editor |

| Home> | DRIVES & MOTORS | >Roller Drives | >Integrated drive solutions |

Integrated drive solutions

16 August 2015

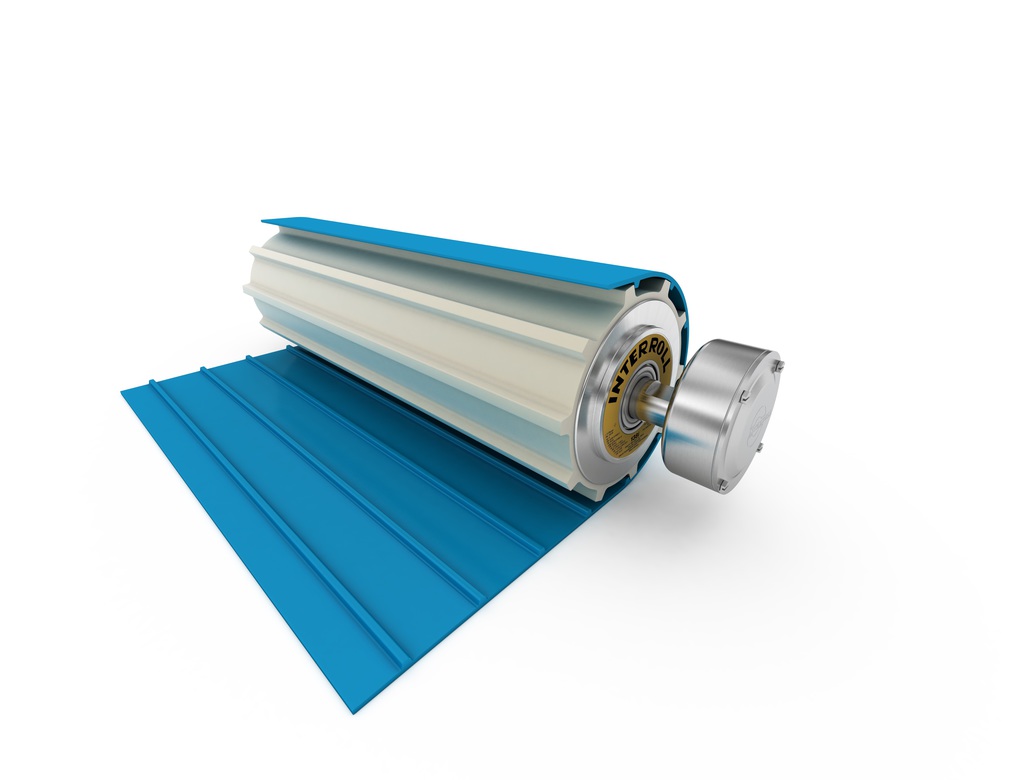

At the PPMA Show Interroll will exhibit details of its range of integrated drive solutions such as drum motors for belt conveyors, its powered RollerDrive and non-powered rollers for conveyor systems.

One key component in the build of modular zero pressure accumulation conveyors and custom built processing/packaging machinery is the energy efficient 24 V DC Interroll RollerDrive EC310, which uses up to 30% less energy and recycles brake energy. They can be supplied with ConveyorControl for use in zero pressure accumulation conveyors or the new versatile MultiControl, a certified network interface card for PROFINET, EtherNet/IP and EtherCAT that directly controls sensors and RollerDrive to offer enormous flexibility.

In pioneering drive solutions for modular plastic belt conveyors, Interroll utilises purpose designed, food quality FDA approved profiled rubber/PU lagging, stainless steel/polymeric sprockets and the Interroll Multiprofile. This is a newly developed profile for use with Interroll asynchronous and synchronous drum motors, which can be used to drive various conveyor belts from different manufacturers using only one Interroll Premium Hygienic PU Profile. Stand F10

- Fully automated material flow

- Innovative pallet & carton handling

- Interroll appoints pallet handling expert

- High-performance crossbelt sorter

- Synchronous drum motor

- Energy-efficient drive technology & powerful drum motors

- Interroll showcases solutions to store & convey efficiently

- Interroll Ltd becomes latest AMHSA member

- Interroll expands performance range of synchronous drum motors

- Interroll raises profile