|

Charlotte Stonestreet

Managing Editor |

| Home> | POWER TRANSMISSION | >Bearings | >Checks bearing authenticity |

Editor's Pick

Checks bearing authenticity

18 December 2015

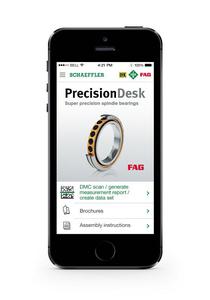

Precision bearing manufacturer Schaeffler has launched ‘PrecisionDesk’ – a new free app for mobile devices that includes a feature for checking the authenticity of high precision rotary and linear bearings.

The app, which can be used on Android, iOS and Windows mobile operating systems, is designed to help maintenance technicians, fitters and design engineers when selecting bearings or installing components.

A new feature of the app is that it enables users to verify the authenticity of rolling bearings marked with a data matrix code. A check is made by simply scanning the data matrix code on the bearing or on the bearing packaging.

This means that app users can use these data matrix codes to access all of the app’s functions, regardless of whether they are using a smartphone or tablet. A web browser-based solution is also being developed that will allow the customer to make use of all the same functions from their PC using a corresponding handheld scanner.

Applications for high precision rotary and linear bearings include machine tools, textile and printing machinery, as well as food processing and packaging plants. In the future, options such as directly accessing bearing-specific measurement records for spindle and rotary table bearings and storing these for documentation purposes, or sending these using the app, will be available.

For spindle bearings, it is also possible to generate bearing-specific electronic data records and, via suitable interfaces, to utilise these in logistics systems, for example. The app therefore offers Schaeffler customers the opportunity to monitor their own bearing inventory and to increase quality levels in the bearing mounting process by efficiently pairing bearings with shafts/housings.

- Dispelling linear guidance system myths

- Increases bearing life

- Frictional torque reduced

- Bearing calculation software

- Effective unplanned downtime prevention

- Schaeffler wins Best of the Best award for AMR

- Linear profile rail system replacement

- More for machine tools

- Plummer block housed

- Schaefler Brakes World Record